Today's barns are increasingly prefabricated buildings in the form of an arched hangar. Modern technologies make it possible, when constructing a cattle farm for 100 heads, to abandon the classical type of structure due to the frameless type. Livestock buildings are now easier to construct and lower in cost. Complying with the required standards, the metal hangar is equipped in accordance with sanitary and hygienic conditions for the efficient maintenance of hundreds of cows.

Choosing a hangar type

The metal is lightweight and easy to use. When creating industrial facilities, it provides significant economic benefits and the shortest installation time. At the same time, facilities with proper arrangement and communications fully comply with the requirements for keeping cattle in favorable conditions.

The popularity of this type of hangar is not without reason:

- construction in the area of the month;

- the creation of a capital foundation is not necessary; support piles or a base in the form of a tape are often sufficient;

- the design is airtight and retains heat well (if it is insulated);

- no welding work, as is the case with frame hangars, which makes construction cheaper and faster;

- Due to the shape of the hangar, most precipitation does not linger on it.

A frameless arched hangar can be easily assembled in a short time, from metal sheets, right on the construction site. The steel is formed to the required parameters and is actually assembled as a constructor using a seam connection.

Search for sales markets and calculation of profitability

At the business planning stage, stable sales channels for products should be outlined. It is known that milk has a short sales period, so spoilage of the product, which promises losses to production, should not be allowed.

Among the possible implementation methods:

- Sales to small resellers, grocery stores for sale

- Wholesale sales to a large processing enterprise as the most attractive option

- Independent processing of milk to produce dairy products: cottage cheese, butter, sour cream, kefir, etc.

- Sales on the market, to private individuals

- Sales to children's institutions, hospitals, canteens

You also need to think through an advertising campaign that can expand your sales markets.

Effective tools will be:

- Creating your own website, group on social networks

- Promotion via the Internet - platforms, forums

- Use of outdoor and media advertising

- Word of mouth

Now let’s calculate the profitability of the business. One cow produces about 5 thousand liters of milk per year. From 50 heads we get 250 thousand liters annually. Based on the average wholesale price of 25 rubles. annual earnings from the sale of milk alone will amount to 6 million 250 thousand rubles, which will make it possible to recoup investments in 2-3 years of work and talk about a profitability of 35%.

Farm location

The barn is located away from residential buildings. It is best to build it over a fairly large area.

The placement location must meet the following criteria:

- Possibility of communication. The main thing is the electrics. It would also be nice to lay a water supply system. Of course, there is an alternative, because you can use an autonomous water supply; the pros and cons of one or another option depend on the location.

- Availability of roads nearby. They will allow easy transportation of cows and products.

- The landscape is best if it is hilly. On a hill, the hangar will be better protected from snow and mud slides in bad weather. During prolonged downpours, the hill will avoid flooding of the barn and avoid a number of flooding problems.

- The minimum distance from a populated area to a field with manure is 200 m (preferably further, since cows emit a strong odor); from the farm to the residential premises – 15 m.

A significant advantage of the location of the barn will be the presence of pastures nearby.

To avoid the risk of contamination of drinking water, farms are located away from wells and hydraulic facilities.

For industrial construction of this type, in addition to the hangar, it is necessary to consider a location for manure and other animal waste.

Purchase of equipment and machinery

An important component of the business plan is the acquisition of machinery and equipment to equip the farm. Its quantity will depend on the number of livestock. Should be purchased:

- A tractor for transporting feed and other agricultural needs worth 300 thousand rubles.

- A mower for making hay for 120 thousand rubles.

- Tractor attachments – 200 thousand rubles.

- Transport for the transportation of dairy products worth 400 thousand rubles.

- Milking machine at a price of 20 thousand rubles. a piece

- Milk cooler – 80 thousand rubles.

- Equipment: buckets, shovels, pitchforks, cans. Drinkers, feeders - 100 thousand rubles.

- Mini-workshop for the production of dairy products and packaging of milk from 900 thousand rubles.

On average, you will need to invest 1-2 million rubles . You can save money by purchasing used equipment and machinery or by skipping some items on the list.

Farm construction stages

Frameless farms can be erected at any time of the year.

The stages of construction of such farms include:

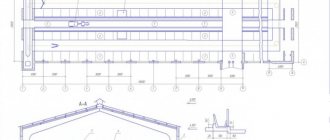

- Development of design documentation for the construction of a livestock farm for 100 animals.

- Construction of a pile or strip foundation.

- Pouring the floor (concrete or laying conventional road slabs).

- Assembly of metal sheets into one supporting structure without the use of welding.

- Construction of production sections for keeping livestock and processing livestock products.

- Complete set of farms for cattle with heating, insulation and other communications, as well as their installation.

- Organization of ventilation in buildings for farm animals.

When building a metal truss, it is extremely important to ensure reliable fixation of the steel structure in accordance with frameless construction technology. This type of work requires the participation of professional craftsmen.

Why is it easy to implement a mini-farm project?

Many aspiring entrepreneurs choose a mini-farm among all the business ideas for family enterprises. This is a profitable business: each cow produces at least 5,000 liters of milk per year. If beginning farmers do not have sufficient funds to start their own business, then future businessmen can turn to the state for help. Financial support is provided to projects on a competitive basis.

To win, you need to present a well-drafted business plan, which is based not only on enthusiasm and the desire to earn money, but on specific calculations.

Beginners in business should not strive to write grandiose projects if they have not yet earned anything. The subsidies given to the winners have limitations: the money received is only enough to buy 25 or 30 cows.

Therefore, there is no point in writing a project designed to purchase a larger number of livestock - 100 or 150 units. In various regions, subsidies are allocated for certain amounts sufficient to implement the project of their own farm for entrepreneurs who are just starting to work for themselves.

For a family business, this option has proven itself to be excellent:

- Everyone who works on the farm does not need to travel by public transport in the morning: the place of work is located near their home.

- When members of the same family are engaged in a common cause, they become more united.

- The automated complex requires simple maintenance. To operate it, you do not need to be a certified specialist.

- Communication with pets has a positive effect on the human psyche.

An example of a small home farm made from scrap materials - To develop a plan for the development of your business, you can use the positive experience of other entrepreneurs who keep 100 units of livestock or more.

- If desired, you can repurpose the business. If initially the farm produced exclusively dairy products, then after some time it is possible to establish meat production.

- The demand for milk and meat products is constantly growing, which guarantees the prosperity of private business.

Today, implementing a farm project has become available to everyone. However, during the design stage, think about every step you take. Postpone the construction of metal outbuildings for the future if there are not enough funds.

Your business will soon pay off completely. The main thing is to think through all the nuances in advance; only under this condition will a new businessman be able to become a reliable supplier of high-quality products of his own production.

All that remains is to maintain your brand, which will allow you to gain your clients. When people are confident that they will be offered only good products from family farms, they will come back to shop again.

Farm lighting for cattle

When designing a frameless cattle farm for 100 heads, it is imperative to include the installation of windows in the project. Implementing them is important work. In a building with windows, drafts must be completely excluded. The barn will receive good natural light if the windows are installed on the south or east side.

Building a farm of 100 heads means placing windows at a height of 1m from the floor so that the cattle are not exposed to chilling.

It is necessary to wash the glass regularly, because dirt on the windows will not let the required amount of sunlight into the room.

Farms do not often have many windows; often after the construction of a barn, high-quality artificial lighting is provided inside.

Hiring

Next, you need to resolve the issue with the farm staff, the number of which will depend on the volume of the enterprise. If you have a KFC, then the number of employees will include family members.

If your farm is medium-sized, then at first you will need at least two milkmaids and two workers . When production is automated, they will work in shifts. Organizational functions and accounting at the initial stage can be carried out by the entrepreneur.

In the future, the staff will be expanded to include other job units: manager, marketer, driver, and support workers. You cannot do without veterinarian services such as the prevention and treatment of diseases of the udder, reproductive system, and hooves. The cost of annual veterinary care will be 100 thousand rubles .

Insulation and heating of the hangar

When keeping livestock on a farm, it is imperative to use a heating system. In a warm room, cows do not lose their weight; in a cold room, it always inevitably decreases, significantly. Therefore, the walls inside the barn should always be dry and warm.

The thermal conductivity properties of steel are low, so insulation requires special attention. High-quality insulation and its correct installation will allow you to significantly save on heating in winter.

The metal structure can either be sheathed with sandwich panels or insulated with polyurethane foam. Insulating the farm for the winter, in the climatic conditions of Russia, is a prerequisite for comfortable keeping of livestock.

Cows tolerate cold better than heat. Therefore, when calculating utility networks for heating, it is important to take this factor into account. Thus, the climate should reduce heat losses in winter and protect livestock from high temperatures in summer.

The desired climate indicators on the farm for cattle per 100 heads are from +10° to +20°. In areas with mild climates, simple eclectic heaters are sufficient. Where winters are long and cold, gas boilers are indispensable.

Insulated frameless hangars for livestock farming are used all year round. Thanks to the addition of sandwich panels or polyurethane foam, the hangar can withstand cold outside down to -50°. Also, insulating a farm hangar reduces noise, protects the facility from overheating and eliminates the greenhouse effect.

Features and formats of dairy farms

A mini-farm with a livestock population of 10 to 100 heads occupies 40% of the market share. An excellent option for a family business, outperforming large competitors in several indicators: increasing the dairy population, milk yield and milk quality

Average dairy farm with a number of livestock from 100 heads and 30% of the market share Will require additional machinery and equipment, staff

A large farm with a cattle population of several hundred cows represents 20% of the market. A difficult option to organize, more suitable for experienced farmers with large investments and long payback

For beginners, it is preferable to choose from the first two options, which are the least expensive and easy to implement.

Barn ventilation

An industrial space for keeping livestock for 100 heads is equipped with an engineering system. Ventilation makes it possible to regulate the microclimate to normalize it. A well-functioning air exchange process eliminates the possibility of condensation forming in the room.

The ideal solution for a barn with a hundred animals is supply and exhaust ventilation. It happens that when a farm is set up on a hill and in a mild climate, farmers think that special ventilation slots are enough, but sooner or later everyone comes to installing active ventilation.

Demand and competition analysis

An important stage of the business plan is to study the market of consumer demand and supply of the closest competitors, their pricing policy and advantages.

The main threat to small businesses comes from large enterprises that manufacture products with long shelf life. They use expensive equipment to pack milk into special containers.

Therefore, farmers are forced to fight for the market with an emphasis on the quality of dairy products. But thanks to government support, private farming has gained a large market share and continues to develop.

Interior arrangement of the farm

Inside, a cattle farm for 100 heads is equipped according to a pre-designed project. A whole range of zones necessary for effective breeding of cows is taken into account.

It consists of:

- Stable.

- Drinking bowl.

- Feeder.

- Litter.

- Manure storage facilities.

- Paddock for walking.

The material used to make the floor also matters.

Stalls

The suitable size of “cells” for cows is 1.2 m by 2.1 m. They are placed in 2 or 4 rows with mandatory intervals. When placing a cow in a stall, it must be tied. For this, a soft and strong rope no longer than 1.5 m is suitable. Calves' stalls are located close to cow stalls, most often through one partition. A properly made stall allows the animal to feel calm.

Drinkers and feeders

Standards for feeder sizes: height – 65 cm; width – 80 cm; length - 1-1.3 m. Boards and bricks can be used to create. It’s easier to make a drinking bowl and a feeding container next to the stalls, on the side of the animals’ heads. The feeder is often made in the form of an oblong trough, which makes it possible to supply food to dozens of cows at the same time. Experienced farmers use metal or plastic as materials - they are resistant to moisture and easy to clean.

It is advisable to have a central water supply. When the farm has 100 head of livestock, it is not advisable to carry water manually.

Bedding

Preferably from natural materials and that the layers are dense. You can use rubber or rubber mats.

Manure storage

Always made from waterproof material. Sloping floors are created in the stalls; waste flows into the storage area using special 20 by 20 cm gutters using special grooves. Such waste can be removed outside the barn through pipes.

Modern farms of 100 heads often implement a floor hydrocleaning system. When keeping a large number of livestock, the solution to using a manure conveyor located along the stalls has proven itself. The best results when cleaning manure are shown by cleaning with a delta scraper unit operating in auto mode.

Corral for walking

To properly raise cows, it is advisable to create a pen for walking. On its territory, livestock can walk and breathe fresh air. “Free” walking has a positive effect on the health of cows.

For a livestock of 100 units, the fencing of the pen should be made reliable to prevent it from being knocked down by animals. It is advisable to install a canopy to protect from precipitation and excessive sun.

The cow pen on the farm must always be kept clean. Any debris and manure must be removed from its perimeter.

Floor

For better cleaning process and hygiene, the floor is made with a slight slope in the direction of the manure receiver. The angle of inclination is 2 cm.

Pouring concrete or cement is completely suitable for arranging the floor of a barn. It is important that the animals do not lie on its “bare” surface. Wooden boards or straw padding as bedding will protect cows from chilling and mastitis.

An alternative to concrete flooring is a floor made of baked bricks. It's warmer. Brick floors are suitable for use for up to 10 years.

A selection of videos: life on the farm - building a barn with your own hands

Start of construction. Preparing and laying out the area for a barn. Welding of frame elements.

Video: building a barn - the beginning

Laying the foundation and erecting the frame. The foundation is made of strip form, formwork is installed, into which previously made frame elements are installed level and secured. The trench is then concreted.

Video: foundation and frame for a barn

Continued construction. Another video report in real time - what we did during the week.

Video: we continue to build a barn

Roof arrangement. The barn design determines the materials that will be used to cover the roof. Inexpensive options are slate and tiles.

Video: barn roof

Laying water pipes. The water supply in the barn begins with a Ø 32 mm riser, to which is connected the main ring main made of Ø 25 mm pipes. Automatic drinking bowls, watering and water taps are installed in the premises.

Video: water supply for a barn

The final stage of setting up the water supply and septic tank. It is necessary to adhere to sanitary standards - when laying water and sewer pipes with a diameter of up to 200 mm in parallel, the distance between them must be at least 1.5 m. It is advisable to lay water pipes in a protective case.

Livestock and feed

A modern pig farm business plan with calculations and a detailed description may be of interest to many aspiring entrepreneurs. For a small farm you need to purchase 50 heads of livestock, of which the majority will be sows. It is better to purchase from breeding farms. First you need to find out which breeds are resistant to diseases and how they gain weight.

Pig nutrition must be properly organized and remain of high quality:

- succulent food

- potatoes, carrots; - concentrated

- barley, rice and other grains; - greens

- alfalfa, clover and other herbs; - food of animal origin.

Financial expenses and income

The numbers will differ in each individual case. Let's consider an approximate business plan for a dairy farm for 50 heads.

Starting investments (in rubles):

- Land rent for a year - 100,000

- Truss installation - 5,000,000

- Connection of communications - 100,000

- Equipment - 2,000,000

- Purchase of 50 cows - 4,000,000

- Inventory - 500,000

- Tractor - 3,000,000

- Feed procurement - 750,000

- Salary to employees for the year - 835,000

- Veterinary services - 100,000

Total - 16,385,000 rubles.

The average yield from one cow is 5,000 liters per year. With 50 individuals - 250,000 liters. The cost of 1 liter of milk for wholesale sales is 25 rubles. Net annual income will be about 6,000,000 rubles.

Business profitability is estimated at 30–40%, which is considered a good indicator. But its payback depends on the volume of products sold, set prices and other nuances.

How to build a barn for 100 heads

To build a strong and durable barn for 100 head or more, you should use a structural approach. This will help not only reduce costs, but also significantly reduce the duration of the project.

Note: In the past, reinforced concrete structures were used to construct such structures. At the moment, this approach to construction is considered outdated and ineffective due to its high cost.

The construction of a modern barn involves the construction of a steel frame, which is then covered with sandwich panels. Brick or concrete is often used as a material for building walls. However, it should be taken into account that in order to ensure an optimal microclimate indoors, brick or concrete walls must be insulated from the outside.

Preparatory work

Starting your own farm requires careful preparation, choosing the type and design of the barn, and making smart decisions. Of course, you need to decide on the size of the premises, the number of individuals, the land plot for development, the purchase of equipment and the purchase of livestock.

Types of barns

The designs of premises for cattle are quite varied. The choice of the most suitable one depends on the breed of animals being bred, the number of heads, tethered or free-stall housing, and the climatic characteristics of the area on the territory of which you can build a barn with your own hands.

They vary in size, material and internal structure. There are warm and cold rooms, depending on what material was used for the frame, walls and covering.

Let's consider several basic design solutions:

- The frame made of metal profiles has proven itself due to its strength, fire safety and durability. In cold climates, it requires insulation with mineral wool or other materials.

- A barn made of sandwich panels is indispensable in the northern regions. It has high heat and noise insulation, protects against moisture and is resistant to corrosion.

- Rebuilding a wooden shed does not require any special expenses, but it will take a long time. As a result, the building will be able to accommodate only 5-10 animals. By contacting a specialist, you can get acquainted with the design options for a 5-head barn.

- The livestock building, built from laminated timber with metal supports, is intended for keeping animals without being tied to a stall.

- Tent barns. The awning is attached to a metal frame using belts and cables. Ease of construction, membrane transparency, fire resistance are not all the advantages of this option.

Selecting a location

The size of the future farm directly depends on the area of the land on which it will be located. It is very important that the pastures are close to the buildings; this will make harvesting hay for the winter simpler and more convenient.

It is necessary to choose a site that allows communications and easy access by special equipment. If you find land on which similar buildings already existed, it is better to choose it, since making repairs will be easier and cheaper than erecting all the buildings from scratch. Having made a choice, the plot is purchased or leased from the local government.

Tools and materials

Having chosen a site and decided on the barn design, you can begin construction.

To do this you will need a set of basic tools:

- shovel;

- crowbar, hammer, chisel;

- construction and laser tape measure;

- knife and construction stapler;

- electric drill;

- concrete mixer;

- hacksaw, chainsaw;

- trowel, hammer-pick.

Tools and materials for construction should be stored in a place protected from moisture. For such purposes, you can set up a barracks or a shed.

Barn size definitions

Typical projects can be divided into:

- mini-farms;

- average;

- large farms.

For small premises (for 1-10 heads), it is quite possible to draw a plan using regulatory documentation yourself. A drawing for building a barn for 1 head is shown in the photo below.

The size of the room is determined as follows:

- 6 m2 per 1 adult cow;

- 4.5 m2 per calf in loose housing.

And do not forget that a certain area will be required for storing equipment and food supplies.

The recommended wall height is 2.5 meters. Low ceilings are not recommended as this will lead to heat loss.

It is noteworthy that animals feel more comfortable in small spaces, in addition, they will be healthier and produce higher milk yields. The construction of a cattle farm for 5, 10 or 20 heads can be done with your own hands or with a small amount of workers and special equipment. To keep 10 heads, the required room dimensions are 36x6 m.

The table shows the main dimensions depending on the size of the herd.

Business Features

The initial investment in the business is quite large, and it pays off in 3–5 years. Farmers should focus on modern technologies for keeping and feeding cattle, use robotic installations and mechanization tools.

Starting investments for opening a dairy farm may vary depending on the following factors:

- Number of purchased animals

- Staff

- Options for providing feed for cattle on your own

- Ownership of a land plot

- Arrangement of the barn

It is very important at the initial stage to decide on all the nuances and, based on this, draw up a business plan for a dairy farm with calculations.