A separator is a device that is designed to separate fractions of liquid substances by density. For example, separating cream from milk, purifying liquids from impurities, etc.

Milk separator Berezka

Most often, it has a device based on the principle of a centrifuge - it has a rotating drum with a drive, manual or electric.

What is dairy processing based on?

Fresh cow's milk is a suspension in which fat globules, called cream, are mixed with the heavier molecules of the rest of the milk. They are easily separated from the bulk of the product by floating. To speed up the separation of fractions, milk separators have been created. Subsequently, the heavy residue is separated into curd mass and whey, but this is after ripening. There are also separators to separate them.

You can separate the cream during separation in any percentage.

If the final result of processing is 1:10, it means that for every 10 liters of skim milk, 1 liter of cream is obtained from 11 liters of milk. This is cream containing a large amount of butter and little liquid fraction. But you can get 3 liters of cream for 8 liters of skim milk. Such cream will be liquid and little butter will be obtained from it. The separator allows you to create a ratio from 1:4 to 1:12.

In everyday life and for the primary processing of milk, small farms use only cream separators or separators, which is the same thing. Cream separation occurs under the influence of centrifugal force, which throws heavy particles to the periphery, while light particles remain closer to the center. After separation, all that remains is to select the fractions into separate containers.

The milk separator is a customized system for the continuous supply of milk into a rotating disc drum and the selection of cream and skimmed milk, or skim milk.

But the process depends on many factors:

- drum rotation speed;

- tasks to obtain a certain ratio of skim milk and cream;

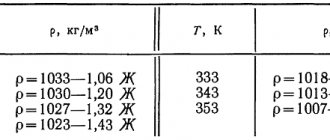

- on temperature and milk flow through the centrifuge.

An experienced user finds his own ratio of all variables and tries to follow it. For the user of a manual device, it is important to catch the required number of drive revolutions manually. The electric milk separator is set up in advance using the mode buttons.

What is a milk separator and why is it needed?

A separator is a mechanical or electrical device designed to purify goat or cow milk and separate the product into fractions. Helps remove impurities from raw materials and obtain heavy cream; it is used in the production of butter, sour cream and cheese. It is a centrifuge in which particles are separated under the influence of rapid rotation.

For processing in the separator, milk is heated to no more than 50 °C

Before the invention of the separator in the 19th century, cream could only be obtained by gravity or settling. The device significantly simplified and accelerated the production of dairy products and almost completely automated the process.

Separator operating principle

Manual and electric cream separators produced by industry are based on the general principle of separating the suspension in a disc drum. This is the main unit; it consists of a package of separating plates placed on a glass and closed with a lid on top. Perforated plates are placed in a certain order, creating 6 holes for milk to come out. For cream, the outlet is closer to the wall of the glass. The product is poured into the receiving bowl of the milk separator. Through an adjustable plug valve, milk flows into the float chamber, and from there it passes down the central glass of the drum.

The milk in the plate drum is separated on each plate by centrifugal forces. Through common channels, the return rises into the receiving chamber and is discharged through the horn into the container. The cream goes into another chamber. Random impurities get into the mud trap. This is how a household milk separator works, regardless of the type of drive. Methods of correct operation and the sequence of operations are reflected in the operating instructions for the separator.

It is mandatory for all household separators to thoroughly wash and dry all parts after milk distillation.

Surprisingly, if the plates are not clean enough or are not put on in the proper order, the machine will not work and milk will flow out of all the cracks.

Criterias of choice

To select the right separator for processing whole milk mass, the following criteria must be taken into account:

- volumes of raw materials, frequency of equipment use;

- requirements for the quality of the resulting product;

- the required volume of containers for receiving cream and low-fat products;

- daily volumes for farming;

- the need to use an electric or manual separator;

- operating conditions, requirements for the design and reliability of the housing.

On average, a standard household separator can process up to 90 liters of raw materials. In this case, the receiver capacity has a volume of ten to twelve liters. The most reliable and practical to use are metal models. They will last longer and are easier to maintain. But their cost is higher than plastic ones, so you must immediately take into account the frequency of use of the device. For example, for farming it is better to choose models with metal bodies. For domestic use and rare use, it would be advisable to purchase a small manual separator made of plastic.

Models of separators for domestic use

When choosing a cream separator, it is necessary to take into account the characteristics of each consumer:

- The one-time volume of processing will determine the choice of the volume of the receiving bowl. The more milk you need to distill, the larger the bowl you will need to avoid adding milk every minute. They produce containers of 5.5 and 12 liters.

- A universal separator will combine the purification of milk from impurities and the separation of cream.

- If more than 30 liters of milk are distilled daily, the best purchase would be an electric-powered machine.

- Metal parts are more durable and have a longer service life, but they are more expensive than plastic separators.

One of the most popular is the Motor SICH separator. This is an open type electrical household appliance for universal use. The marking depends on the output measured in l/hour. The separator can operate for an hour, then a break is required to cool the motor. The connection to the separator is made through a gearbox and an adapter coupling. The milk receiver is designed for 12 liters. The skim milk can be reduced to 0.05% fat content. The ratio of cream to skim milk can be 1:4-1:10. Such a unit costs from 6.5 thousand, depending on the configuration and the material used to make the working part.

The milk must be heated before separation. If you don’t have a thermometer at hand, the milk should be equal to the temperature of your fingers, which means that your finger feels the milk is slightly warm.

You need to open the tap and put milk into the system after the separator picks up speed, warms up, and idles for about five minutes.

The Farmer separator differs from the previous device by a higher speed of rotation of the disc drum, 1450 rpm, which means a more efficient separation of milk into cream and skimmed milk. The drum rotation speed is adjustable. The device weighs only 3 kg.

Manual separators RZ OPS are designed for low productivity. The set includes a 5.5 liter bowl. The plastic version of the separator costs 3 thousand, the metal version is twice as expensive.

Design

The design is a metal cylinder divided inside into containers. Partitions are used as dividers. The installation of the oil and gas separator NGS can be vertical or horizontal. For reliable fixation, special supports are provided on the body.

The choice of equipment according to the installation method (horizontal or vertical) depends on the characteristics of the working environment, installation conditions and the throughput of the separation system.

- The horizontal one copes better with the assigned tasks with large volumes of oil inflow.

- A vertical oil pumping station serves a smaller flow of oil, but also takes up less space. Such designs are convenient in terms of cleaning the inside of the container (walls, bottom) from deposits formed during the separation process.

The bottom of the oil and gas separator is equipped with pipes and fittings - through them the working medium is pumped in and process equipment (regulating, control, measuring) is connected. Each of the compartments (tank sections) has its own fittings through which the separated oil and gas are discharged.

How to make your own milk cream separator

However, craftsmen have come to the conclusion that they can create a milk separator with their own hands, using the same centrifugal force. The diagram shows a simple apparatus that separates cream and skim milk into fractions.

When rotating under the influence of centripetal acceleration, the heavier the particle, the further and with greater force it is thrown. If you take a vessel, pour milk into it and give it a sufficient rotation speed, the liquid will separate. The light fraction will be closer to the center, and the water part will concentrate on the rotating walls and will tend to fly out further.

A hole is made in the rotating cylinder with a thin needle. It is placed in a stationary vessel that will receive splashes. It is important to know the amount of skim milk you are taking. This is determined before the separation begins. The remaining part in the inner cylinder is the light fraction, cream.

And the more skim milk is selected, the thicker the cream will be.

This homemade separator allows you to process only one portion of milk, after which you can make a new load. Torque can be transmitted from any engine. The drum rotation speed should be no more than 1400 rpm.

Another principle of milk separation is vibration, but it has not found application in household milk separators. Magnetic separators for separating cream from cold milk and whey from cottage cheese are used in industrial processing, model A-1 AXO.

How to choose an oil and gas separator

When choosing a device, key attention should be paid to the purpose of the oil and gas separator . Starting points are the type and nature of the petroleum product being serviced, processing volumes, stability, system pressure, temperature.

It is necessary to choose between the two largest classes - horizontal and vertical separators NGS - taking into account the conditions of future operation. The vertical option, for example, demonstrates greater efficiency, but will cost more, therefore it is better suited for enterprises with high productivity of technological processes.

A horizontal gas station is cheaper, but more expensive to maintain. In addition, it uses more separation cycles: to increase the productivity of the devices, the oil is heated, only then mixed (separated) and the pressure is reduced. All this, however, does not prevent horizontal separators from being in higher demand (largely due to the effective balance of price and performance).

Pomeranian discussions on the forum

Spitz color Help me understand what color the baby will be? In the metric it is cream, the breeder said it will be cream. But there is a lot of gray that confuses me... will it bloom with age? Or wait for some kind of cream sable? Age 2 months. Mother…

Diet, recipes for gastritis. Please tell me any recipes on what to cook for gastritis, pancreatitis from natural food?

Help us understand what type of Spitz puppy will be. Help us determine the type of Spitz puppy.

Help identify the puppy! They are urgently offering a puppy, a Spitz, there is a photo. Help me understand if this is a mixture with an unknown breed.

Separation

Milk separator

During the operation of any separator, there is no change in the chemical composition of the separated substances. The qualities that distinguish separation products do not necessarily coincide with the characteristics by which the mixture is separated in separators. Many individual small particles take part in the operation of the separator, among which there are particles with intermediate properties in relation to the necessary characteristics. From the initial mixture after industrial separations, absolutely pure fractions of the separated components cannot be obtained, only products with a predominant content of them.

Separation

Milk separator

Main article: Separation

During the operation of any separator, there is no change in the chemical composition of the separated substances. The qualities that distinguish separation products do not necessarily coincide with the characteristics by which the mixture is separated in separators. Many individual small particles take part in the operation of the separator, among which there are particles with intermediate properties in relation to the necessary characteristics. From the initial mixture after industrial separations, absolutely pure fractions of the separated components cannot be obtained, only products with a predominant content of them.