Typical barn designs

Most often, large modern livestock farms and complexes are located in buildings that have survived from Soviet times. Converting an old building is much cheaper than building new space. This is especially true when it comes to large livestock and a barn for 100 heads or more. Old buildings are distinguished by their reliability and convenient layout: very often the buildings are interconnected, have a special room for organizing a dairy shop, a maternity barn, a separate barn for calves, young bulls and heifers, and breeding stock. With the same success, you can convert an old stable or pigsty or sheepfold into a cowshed.

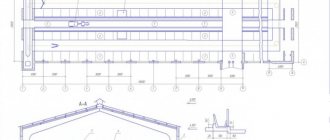

Barn project for 200 heads

In modern livestock farming, farms are most often built from scratch for livestock from 50 to 200 cows.

For larger livestock, it is more profitable to find and refurbish a ready-made barn. At the first stage of planning and creating a project, it is necessary to decide on the number of cows and the maintenance system. This can be stabling, in common pens or on a leash.

It is most convenient to use a standard barn design - a one-story building with a wall height of about 3 meters, an insulated roof, and a maximum height under the ridge of 3.5 meters. At this height, good natural air circulation will be ensured. For construction, it is better to use a material that is suitable for the given climatic conditions, economical and environmentally friendly. Most often used:

- Metal,

- Sandwich panels,

- Foam concrete,

- Brick,

- Beam.

Basics of building construction technology

The construction of a barn for a mini-farm is carried out according to the following plan:

- digging a pit for a strip foundation;

- pouring the base (necessarily with reinforcing mesh);

- walling;

- installation of floor beams;

- roof assembly;

- installation of windows and doors;

- connection of communications.

The barn can be solid or frame. For the foundation, concrete on a sand cushion is used. Immediately consider the angle of the floor.

Use metal or concrete for flooring, and brick, foam concrete or wooden beams measuring 10x15 cm for walls. A frame building can be covered with sandwich panels (especially in cold regions). A gable roof is preferable - snow and water flow off it more easily. Roofing materials - roofing felt, slate, corrugated sheets.

Advice. The attic will make the room warmer. The floor on it is made of boards, which are covered with a layer of sand.

Materials for the barn must be durable and environmentally friendly. This way you will create a good microclimate indoors. And it, in turn, is important for effective cattle breeding.

Features of barn ventilation

Natural ventilation in a typical barn is provided by the presence of small windows under the roof ridge. And forced ventilation of the barn requires a special tunnel or circulation fan device. Such fans are most often installed under the ridge of the roof, and can operate either automatically or be turned on as needed.

Summer barn, tent hangar

Types of cow sheds

If we consider the material of construction, the barn can be:

- a room made of metal profiles, where the room temperature is identical to the street temperature;

- construction made of heat-insulating material;

- hangar based on sandwich panels.

There are several types of barns depending on the design of the premises:

- a 2+2-row barn, in which a high trapezoid-shaped roof is made of a metal profile, and inside there are side walls with curtains;

- 3+3-row barn, characterized by the presence of a “carousel” milking row and a separate building for storing milk;

- 3-row barn, where the milking area and the calf room are in the same room.

Typical dairy farm project

Typical dairy farm projects designed for large livestock (from 400 to 2800 or more heads) have their differences. The construction of such a livestock complex should include eight sections. Each section will be occupied by cows selected according to physiological and biological parameters (age, milk production, lactation period, etc.).

The design of a complex for keeping cattle with a livestock of 2000 animals often includes premises for organizing a dairy plant. For a large farm, this is more profitable than selling milk in large volumes to third parties.

Modern barns designed for large numbers of cattle must be at least 102 meters long (for 460 animals) and at least 120 meters long (for 1100 animals). Typically, a typical dairy farm project involves keeping cows freely without a leash, in boxes, on a bed of straw or sawdust.

Barn project general view

A large dairy farm also involves the organization of a milking parlor equipped with automatic milking equipment. It will take two employees about four hours to service a herd of 400-600 head, while larger herds typically require three to five milking parlor workers.

In addition to the milking and birthing parlor, a typical dairy farm design includes:

- Veterinary inspection and quarantine area,

- Transport hall,

- Feed storage warehouse,

- Office premises for employees,

- Veal barn,

- Vehicle scales and disinfection system,

- Garage,

- manure pit,

- Fire tank.

All large commercial dairy farms are equipped with special devices that distribute water and feed automatically.

For a farm of 600 heads, the minimum required is about 1200 hectares of land. And the annual productivity of such a complex will be about 8,000 tons of milk and 200 tons of meat. The construction estimate from scratch will be more than 350 million rubles.

Features of the barn design for 100 and 200 heads

The design of a barn for 100 heads most often involves keeping cows tied in stalls, since this is a more economical option. Stall size for one animal: length 2 meters, width 1.2 meters. The floor in the barn is designed taking into account a slight slope of no more than 2.5 cm. This makes cleaning the entire room easier. A typical barn plan includes utility rooms, a cesspool, a water system, heating, electricity, as well as marking out the installation of the necessary milking equipment.

Calculation module for design

The design of a barn for 200 heads is different in that it involves the arrangement of stalls in four rows. A 200 head barn is the same as a 100 head barn with an area of less than 1500 sq.m. does not require passing state examination.

Features of the barn design for 50 heads or less

For a homestead, where there are from one to five cows, a cattle shed is much more common. Cows are often kept together with goats, poultry, piglets and other domestic animals. If there are more cows, then farmers build a private dairy farm using a barn design for 20 heads or more.

According to one standard project, you can build a barn for 5 heads or a barn for 50 heads: there is no significant difference in construction.

You can build such a farm yourself, without the help of construction companies. You just need to decide on a sufficient plot of land, develop a farm plan that would take into account the supply of all communications, an air exchange device, separate stalls for breeding bulls and dairy cows, as well as a cesspool.

Barn for 1 cow and calf

A detailed diagram of the farm should also include a room for storing equipment, marking stalls and aisles with all dimensions, the location of switches and sockets, and water taps.

Feed distribution

The total power supply of the barn is calculated taking into account the automatic supply of animal feed. For this purpose, a conveyor belt is used. The equipment requires a separate calculation of electrical supply.

Feed dispenser

When choosing a feed dispenser, the following needs are taken into account:

- number of heads in the herd: 200;

- single feed consumption rate: 16 kg per 1 individual;

- distribution time – 20 t/h.

By studying the characteristics of the equipment provided by the manufacturer, they can conclude whether the feed dispenser will be effective for supplying feed to a large number of animals. TVK-80B equipment fits these parameters. Its productivity is 38 t/h, the number of livestock served is 100 heads, the length of the feed chute is 74 m. The power of the device is 5.5 kW. Requires an electrical voltage of 220 V.

Choose a feed dispenser RK-50. The conveyor is located above the feeders. Its productivity is 30 t/h, designed for 200 heads. Power 9 kW. Belt length is 75 m. A separate electrical system for the chopper and feed loader is prescribed if the processes are automated.

Feed dispensers can be powered by an AIR100L2U1 engine, PML-262102 engine starter: “start” and “stop” button. Thermal relay RTL-101604, a way to regulate current 9.5-14 A. It is installed on the drive of the feed conveyor. Before accepting equipment, its performance is calculated. To drive the waste collection conveyor, use an AIR90L2U3 engine, a PML-122002 starter, an RTL-101204 relay, 7-10 A. Automatic switch AE 2046.

Barn Construction Methods

Before you build a barn with your own hands, you need to prepare the site for construction. A layer of fertile soil is removed from the site, after which the site is covered with medium-sized crushed stone. This preparation of the site ensures that the foundation is sufficiently solid. When building a barn yourself, two methods are used: frame and frameless.

Frame method

Building a barn using this method is more economical. Immediately after preparing the soil, installation of the frame begins. First, the support of the future structure is laid in the base in the shape of a square, then they begin to install the support pillars. All supporting elements are connected to each other using a welding machine.

Typical frame barn for 200 heads

Frameless method

The second method is frameless and involves the mandatory construction of a foundation. There are two ways to build a foundation correctly. First: we build the formwork and fill it with concrete. Second: we fill the dug trench with rubble stone and burnt brick, and connect them with cement. If the soil is not loose, then the depth of the foundation is about 60 cm. The walls are erected directly on the foundation, without using any support pillars.

Security

There are many electrical devices in the barn: motors, power cabinets, panels. Heaters are located in drinking bowls and water containers. All devices must be safe for both operating personnel and animals. It is required to ground the housings of all electrical installations. Why is this necessary if the devices are securely enclosed in housings?

Grounding barns is necessary not only for safety reasons from electric shock. If a short circuit or breakdown occurs, the current will flow through the metal objects of the barn: pipes, partitions in stalls, metal feeders, drinking bowls, conveyors. To prevent this from happening, electrical outlets are made. They are connected to all metal objects and to the ground. The current will follow the path of least resistance, through the tap. A separate system is provided to protect the building from lightning strikes.

Grounding of devices is carried out in a place inaccessible to animals. Do not install the system in passages, near stalls or in animal resting areas. Choose a protected area that is clearly visible and has access for repairs.

More on the topic: What is cow launching and how to do it?

To protect animals from electric shock, metal conductors, wire or tape are placed on the floor of the barn. They are connected to metal partitions, feeders and other elements. Connections are made by welding. The peripheral conductors go to the central metal rod. Its length is ½ the length of the stall. Diameter – 12 mm.

The protective conductors in the power cabinet or in the central panel are connected to the triangle of the repeated grounding loop. To do this, use corners 5 * 5 * 0.5 cm. Between them there is a steel strip - 4 * 0.4 cm. The distance between the electrodes is maintained at 2.5 m. It is buried to a depth of 0.5 m.

General principles of construction

In farms engaged in breeding and keeping cattle, the minimum height of the walls should be about 2.5 meters, and the ceiling height along the central aisle should be at least 3.5 meters. When designing walls, you should definitely consider the presence of windows. To reduce electricity costs, it is recommended to make the number of windows equal to the number of animals. So, in the walls of a barn for 20 heads there should be at least twenty windows. After the walls are erected and the roof is covered, they begin concreting the floor and constructing internal partitions.

Organization of the delivery room

When thinking through the drawings for the construction of a barn, it is necessary to mark out not only the main room, but also the maternity unit, the feeding area, the walking area and the milking parlor.

The birth hall is located in the warmest part and is equipped with double doors. This will help avoid drafts. In the birth stall, they make larger stalls (for a cow with a calf, at least 10 sq.m. is required), additional lighting is provided, and automatic drinking bowls are installed. The stall is covered with double bedding. It is very important to provide water supply with convenient taps in the delivery room. All partitions are made only from wood.

Organization of feed

Each stall must be equipped with a feeder and a manger for hay, as well as a drinking bowl or automatic drinking bowl. But it is also important to organize a place to store feed. Hay and straw are most often stored under a shed next to the barn, but concentrated feed and grain should be stored indoors. Typically, barns have a separate room for feed. Several shelves are made in it, a bath is installed (for steaming food and preparing mash), as well as several containers with a convenient lid system for storing grain. In the stern you can also put a small refrigerator for storing oils, medicines, and liquid fertilizers.

Organization of a milking parlor

Even on a small farm it is better to provide space for arranging a milking parlor. For a livestock of 10-20 cows, it is enough to equip two stalls, next to which milking equipment should be placed, with convenient access to electricity and water. The stalls must be equipped with mangers for hay. Stalls are made from both metal pipes and timber. The most convenient option for a milking device for small livestock is a pair milking machine.

Set of documentation for a barn

The milking parlor should have both good lighting and good ventilation.

On large farms, a separate room is allocated for the milking parlor, where complex milking equipment and a milk pipeline system are located. The layout of the milking parlor and the layout of the stalls directly depends on the number of cows and the milking machine used.

Water supply

Watering cows on large farms is fully automated. With the tethered method of keeping cattle, individual drinking bowls are installed in the stalls. For free-stall keeping of animals, common drinking bowls are installed. Water is supplied to them from a central reservoir through a pipeline.

In general drinking bowls, filling occurs due to a float device. Individual bowls use a valve to supply water. The animal approaches the bowl, pressing the valve with its head, water is supplied.

| № | Helpful information |

| 1 | PE-2 – used for general watering of cattle. The drinking bowl is designed for 120 heads, volume 140 liters. Heater – 270 W |

| 2 | AP-1A – individual drinking bowl. The bowl is placed between 2 stalls so that 2 individuals can drink at once. Volume 1.85 l. Heating in a total capacity of 270 W. Assumes 80 liter tank |

| 3 |

More on the topic: Why does cow's milk taste sweet?

To ensure that the water in the drinkers remains warm for a long time, they are placed in thermal pipes. They are made of plastic. They have double walls and thermal insulation. The drinking bowls are connected via a SUEVIA 230/24 V transformer.