Organizing your own business in rural areas is a promising idea. This is especially true for the business of breeding cattle for the purpose of producing milk and meat.

This can be a small peasant farm with up to 10 or 20 heads of cattle, that is, a family farm, or the creation of a large production with a head of 100 or more cows. Due to the difficult situation that has developed in the state, investments in cattle breeding are very relevant. In addition, there is always a demand for food products in the form of meat and milk. And in the context of imposed sanctions, import substitution, state support for agricultural enterprises for milk processing and meat production, they are especially valuable.

The main thing is to have a great desire, start-up capital, and a good business plan. A business plan for a dairy farm is the basis that will allow you to provide for all stages of the development of a business. It will display the main points: necessary equipment, financial investments, payback time and profit. You will also need to arm yourself with some knowledge on cattle breeding, milk processing, including the basics of meat production.

First steps in opening

Step one. You need to start by finding a place in the countryside where you will open a dairy farm. An important parameter in this matter will be the area of land, the presence of nearby pastures that will allow keeping cattle; 10, 20, 50, 100 heads. Creating a business plan should clearly provide for this.

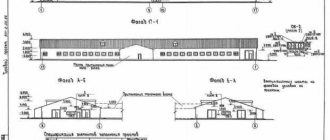

Step two. The place for cattle breeding can be a former farm or old-style premises. This “ready-made” option is more profitable than the option of building even a small workshop for 10, 20 heads, not to mention 50 and 100. In addition, construction requires paperwork for construction. It is easier to rent the space of a former farm and carry out renovations there.

Step three. To keep cattle, you need to ensure a temperature of at least 12 degrees. In addition, for this area it is important to provide cows with grass feed in the winter. At the same time, in the summer, providing cows with feed can be practically free. On pastures there is enough food for the entire herd: for 10, 20, 50 and even 100 heads.

Step four. Creating a profitable dairy farm requires purchasing a breed of cow that has high milk yield. This will allow you to count on a shorter payback period, including greater profits.

Step five. If you have little capital, then you can start a business with a family farm of 10 or 20 heads. Subsequently, it will be possible to increase the livestock by creating workshops for hundreds of animals from the family farm.

Step six. For a faster payback, it makes sense to buy a mini workshop of a dairy plant for processing milk into dairy products and packaging them in bags. This way you can expand your business.

How to build a barn for 100 heads

When planning the construction of a premises for breeding cows, it is necessary to carefully calculate its area. Building a modern barn with your own hands is a difficult task. It is better to entrust the work to qualified craftsmen. After all, even the most insignificant omitted detail can lead in the future to serious problems in the functioning of the premises and violation of the rules for keeping animals. When determining the dimensions of the barn, consider:

- principle of keeping cattle;

- number of goals;

- availability of additional utility rooms.

The division into workshops must be planned at the stage of project creation. It is advisable to make the most of every meter of space, but at the same time comply with all sanitary standards.

Materials

For any farmer or investor, the cost of the structure being built plays an important role. The price depends linearly on the materials that are planned to be used. For example, if winters in the region are cold, it is advisable to build a permanent warm barn. The ideal option is to use sandwich panels, characterized by excellent thermal insulation and sound insulation.

When constructing cold buildings (for regions with a temperate climate), the most popular type of enclosing structures is corrugated sheet metal (metal profile). The fencing is strong, durable and reliable. If necessary, the wall panel of the structure can be insulated at any time. Various thermal insulation materials, such as mineral wool, penoizol or extruded polystyrene foam, are suitable for this.

Foundation

To build a barn for 100 heads, it is necessary to prepare and clear the area and select the foundation. The type of base depends on the massiveness of the structure and the characteristics of the soil. LSTK and LMK are lightweight, and therefore there is no need to equip a capital foundation. When constructing a barn, it is advisable to use the following types of load-bearing structures:

- strip foundation - a shallow foundation is rational in low-rise construction. It is necessary to outline the perimeter of the future structure, drive reinforcement into the ground at the corners, check right angles, and make internal markings. After digging a pit (at least 400 mm deep), you can begin arranging a sand cushion (at least 150 mm thick). Pieces of plywood or boards are suitable for installing formwork;

- pile - in this case, piles are used as supporting elements. The foundation evenly distributes the load on the ground and is not subject to cracking and shrinkage. The arrangement of the foundation includes several stages: marking the base lines (field contours) and immersion points for each pile, driving the structures into the ground, tying them, and arranging the formwork.

The use of LSTK and LMK, in comparison with a reinforced concrete frame, will save about 20% of funds on foundation construction by reducing the volume of excavation work, reducing material consumption and logistics costs.

Walls

The metal frame for sandwich panels is the load-bearing part of the future building. For the manufacture of a metal frame, as a rule, welded or rolled I-beams, channels, and thin-walled cold-rolled profiles are used.

Please note: The structure is installed on a buried or shallow foundation, a thin-walled bent profile is used as purlins, the distance between the ribs must be at least 50 cm.

The wall panels are fastened using self-tapping screws. Next, all the floors, both from the bottom and from the top, are hemmed.

When planning a prefabricated building, one of the first issues that have to be resolved during the development of the project is the choice of the type of sandwich panel insulation. The structure can be insulated using mineral wool, penoizol or extruded polystyrene foam.

Roof

After erecting the walls, it’s time to proceed to the next stage - arranging the roof. For large barns, it is advisable to use wooden floors and gable structures, roofing panels and C-profiles or trusses with U-profiles. It is advisable to trim them with inexpensive slate sheets.

Floors

As for the flooring, it must be moisture-proof and chemical-resistant. Give preference to rubber-cord, cord-rubber-bitumen and expanded clay-bitumen flooring - durable and low-maintenance materials. Be sure to keep in mind that the floor should have a slope of 3-5%. Thus, waste products will flow into the slurry gutters themselves.

Litter selection

One of the most important tasks is choosing the optimal covering in stalls. It is not recommended to keep cattle on a cold concrete floor, otherwise the cows will suffer from mastitis. Bedding for cattle can be prepared from various materials, the main thing is to make sure that they are practical and comfortable for the animals. Most farms most often use:

- straw - to prevent the appearance of fungi, each layer of coating is sprinkled with special antiseptic powders;

- sawdust - quickly absorbs moisture, but absorbs odors quite poorly, so you will have to replace the layer every 2-3 days. This option is good for large farms with a sufficient number of staff;

- rubber plates - dry quickly, protect from cold, are durable, do not allow moisture to pass through, are easy to use, and are reusable.

In Europe, farmers actively use bedding made from recycled manure. In our country, agricultural producers are just beginning to practice this method. The material consists of undigested feed residues, which are passed through a filter-drying apparatus, resulting in a brown mass. However, such litter is suitable only for regions with a dry climate; in conditions of high humidity, the material gradually turns into manure.

Heating

The most common today are water heating systems with natural circulation or with pumping in the presence of central boiler houses that supply heat to a group of rooms. To heat the milking parlors and the entire facility, you can use gas burners, infrared emitters or incandescent lamps. It is very important to follow the necessary regime, which is to maintain a temperature of 18-20°C.

Ventilation

Each type of ventilation system has its own installation features. Improper installation of devices can lead to disruption of the indoor microclimate, overheating, and stress in animals. Therefore, when choosing a suitable system, consider:

- barn size;

- ceiling height;

- number of goals;

- features of air flows.

The process of creating ventilation consists of several stages. Ventilation ducts must be secured to the roof of the barn; the distance between them must be at least 2 meters. Next you need to install the channels on the walls. The optimal distance between them is 3 m, with a height from the floor of at least 2 meters.

Lighting

It is important not only to correctly observe the length of daylight hours, but the intensity of light at the level of drinking bowls and feeding table is decisive. It is believed that the optimal intensity is between 150 and 200 lux, although brighter light is allowed - up to 300 lux.

Barn lights must be made of materials that are resistant to chemically aggressive environments. LED lighting allows you to reduce operating costs for maintaining a lighting installation and achieve maximum energy efficiency.

Manure removal

The most effective solution is considered to be a rod-scraper mechanism operating in the transverse and longitudinal direction. When choosing a design, it is necessary to take into account the climatic characteristics of the region.

The easiest way is to create an open manure storage facility. To do this, you need to dig a 3*3 m pit and insulate its bottom and walls with film. This will prevent liquid waste from penetrating the soil and groundwater.

Please note: For regions where rain is not uncommon, closed manure storage facilities in the form of large barrels or tanks are suitable. The raw materials rot with maximum nitrogen retention, forming high-quality fertilizer.

Interior arrangement of the barn

When creating a standard design for a barn for 100 heads, it is necessary to take into account not only the size of the cattle, but also the space that will allow the animals to perform basic maneuvers. Cows should be able to lie down in the stall in their natural direction. This is very important, because any interference, insufficient height of the overhead beam, negatively affects the productivity of livestock and causes stress.

The area of the barn directly depends on the volume of livestock and the number of rows in the structure. When determining the overall dimensions of a modular building made of LSTK or LMK, be guided by the following recommendations:

- floor area per cow is 6 sq.m;

- for a cow and a calf you will need at least 11 sq.m;

- The width of the service passage varies from 1.2 to 1.5 m.

Another important point. There are designs for tethered and loose cattle housing. In the first case, animals are placed in individual stalls on a leash. In the second case, barns are divided into sections in which cows are kept in groups (no more than 100 heads) in one box. Boxes are arranged in the same way as stalls, in several rows. In this case, one cow will need 2 m in length and 1.2 m in width.

Please note: It is optimal to build a building for housing cows from LSTK or LMK - it is economical, fast, and reliable, but only if the assembly is carried out by professionals.

Dairy Farm Business Plan

We will consider creating a farm by renting premises and land for 50 dairy cows with a subsequent increase in the number of livestock and expansion of the business line. To open a business, you need start-up capital, which in some cases is not available. In this case, you can take out a soft loan, which is given to help beginning entrepreneurs in rural areas.

At the same time, it will be necessary to:

- Register a legal entity in the form of an individual entrepreneur;

- Before starting production, you need to open personal accounts for communications, undergo fire and veterinary inspections;

- You will also be required to submit quarterly and annual reports. You will need to think about an incoming accountant or do the accounting yourself;

- In addition, regular examination of the cattle by a veterinarian will be required.

The presence of all permitting documentation, as well as veterinary control, will make it possible to sell both milk and dairy products and cattle meat, ensuring the costs of organizational issues, vaccinations, eliminating defects, and the like will require up to 50 thousand rubles.

Total: 50,000 rubles.

Advantages of frame-awning options

Arranging livestock housing inside hangars is beneficial for a number of reasons:

- Low cost of construction (three times cheaper than an analogue made from traditional building materials), which means higher profitability of the entire enterprise; high speed of installation and commissioning;

- The ability to quickly modernize equipment or completely change production;

- The ability to quickly dismantle and build a calf barn, pig barn or barn at any other place at minimal cost;

- Thanks to better ventilation of hangar rooms, it is much easier to deal with dampness;

- Frame buildings do not require a permanent foundation. This allows them to be built without preliminary preparation and on almost any soil.

If you contact our company for services, you will be able to verify the practicality of frame-tent barns personally. We work in all major regions of Russia: Moscow, St. Petersburg, Yekaterinburg, Samara, Novosibirsk, Nizhny Novgorod, Rostov-on-Don, Chelyabinsk, Voronezh, Krasnodar, Magadan, Yuzhno-Sakhalinsk.

Rental cost and repair work

A farm with 50 cows will require hiring people. Therefore, production, office, utility and other premises should be included in the business plan. For a production of 50 heads, taking into account subsequent offspring, an area of 1250 square meters will be required. Taking into account the expansion of production, it is recommended to rent premises with a small reserve. Today you can rent premises of former farms for 100-200 rubles per square meter.

At the same time, the rented farm may not be ideal; repairs and mandatory disinfection may be required.

The rental cost is 100 rubles per meter, including repairs and disinfection - 200 per meter.

- 1500*100=150,000 rubles – monthly rental price.

- 1500*200=300,000 rubles – the cost of repairs.

Total: 450,000 rubles.

Purchase of equipment

Machinery and equipment for a dairy farm are an important component, because without them it will be quite difficult to manage.

- Tractor for household needs, transportation of feed, removal of manure, Price - 300,000 rubles.

- Mower KRN-2.1. Price – 120,000 rubles.

- Rakes and tedders, as well as other attachments necessary for the production and preparation of hay. Price – 200,000 rubles.

- Gazelle to transport milk, meat for sale, feed, meat and the like. You don't have to buy a new one. Cost – 400,000 rubles.

- Milking machines for automatic milking of cows. 5 items. A total of 100,000 rubles.

- Auxiliary equipment, including office equipment, buckets, cans, containers, shovels, forks and other tools – 100,000 rubles.

- Mini workshop of a plant for the production of dairy products of the Kolax-503 type. A modular mini workshop of a plant for processing milk into dairy products can provide: pasteurized milk, packaged in plastic bags, kefir drink in bags, sour cream by weight in bags, cottage cheese by weight and the like. The mini workshop of a dairy plant for milk processing is supplied in a modular version and is connected to communications. A mini workshop of a dairy plant of the Kolax-503 type costs from 900,000 rubles.

Total: 1,920,000 rubles.

Governmental support

Beginning agricultural entrepreneurs can count on financial government assistance. It can be:

- Subsidies for the sale of quality goods in the form of raw milk

- Return on investment for refurbishment or modernization of the farm in the amount of 40%

- Assistance in paying interest on a loan taken from a bank to start a business

- Assistance in purchasing highly productive livestock in the amount of up to 50% of the cost

Such programs differ in each region, so check their features and conditions of participation. Some of them are provided only on a competitive basis. Refunds and subsidies are provided over time, for example after 2 years or even later. Therefore, you need to have your own funds to open a farm and keep it afloat for the first time.

Buying cows and feed, renting pastures

- Dairy cows – 40,000 rubles each (50 in total). Total 2,000,000 rubles.

- Rent of pasture land – 300,000 rubles per year;

- Hay – 300,000 rubles per year;

- Concentrated feed – 180,000 rubles per year;

- Salt – 20,000 rubles per year;

- Insemination – 50,000 rubles per year;

- Expenses for veterinarian services, medications, including other expenses - 100,000 rubles.

Total: 2,950,000 rubles.

Staff salaries

To maintain a dairy farm with a livestock of 50 animals, taking into account height, at least 4 people are required:

- Manager – 25 thousand rubles;

- 2 milkmaids – 20 thousand rubles each. Total 40 thousand rubles.

- 2 handymen for 20 thousand rubles. Total 40 thousand rubles.

- 1 tractor driver – 25 thousand rubles.

Veterinarian services will cost 20 thousand rubles. A visiting accountant will cost 15 thousand rubles. At the same time, with their consent, you can pay the staff partially with dairy products, that is, using commodity-money relations.

Total: 165,000 rubles.

What does the construction of turnkey barns include?

Turnkey services may include: only the construction of a building or livestock complex, or a building fully equipped for a barn.

Main stages:

- Receiving technical specifications and creating a project, preparing all documents.

- Foundation construction.

- Construction using one of the prefabricated technologies.

- Floor installation.

- Installation of engineering and other systems.

- Installation of technological equipment for the barn (if this work is provided).

- Delivery of the object to the customer.

Next, we will consider these stages and technologies in more detail.

Total costs, payback period

In order to open a dairy farm for 50 heads, you will need to spend the following amount:

50000+450000+1920000+2950000+165000+50000=5585000 rubles.

Monthly profitability. Farm income will be determined by the productivity of the dairy herd, as well as the selling price of milk and dairy products. The average milk yield of a cow is 5000 liters per year, which we will take as a basis. Over the course of a year, 50 cows will provide approximately 250,000 liters of milk. The wholesale price of a liter of milk is in the range of 15-20 rubles. Taking into account the added cost of 40-50% when processing milk into dairy products at a mini plant, you can count on 22-30 rubles per liter. As a result, the dairy farm's revenue will be 250,000 x 25 = 6,250,000 rubles per year. After some time, revenue may increase, as the livestock will grow, and part of it can be sold for meat.

Subtracting current expenses from this amount, we calculate profit for the year:

6250000-150000*12-300000-300000-180000-20000-50000-100000-165000*12-50000*12=2120000 rubles per year. The monthly profit will be 176,666 rubles.

Dairy farm payback time:

5585000\176666=31.6 months.

That is, it will take almost 32 months to recoup a dairy farm.

Registration of activities

Those who keep several bulls do not have to register their business activities. As the livestock increases, the issue of paperwork will still have to be resolved. By contacting the tax service, you need to write an application to open an individual entrepreneur and choose a simplified taxation system with a deduction rate of 6%.

Attention! In addition to registering the activity, you will have to obtain a license and certificates confirming the quality of the meat. Without these documents, it is impossible to sell finished products in large volumes.