Poultry meat yield:

The output of deboning broiler chickens with an emphasis on the production of boneless breast meat.

| name of raw materials | Percentage of yield to weight of broiler chickens, % |

| Ham leg n/a | 33% |

| Used breast | 20% |

| Wing n/a | 11,5% |

| Frames (including soup set) | 34,5% |

| Technological losses | 1% |

Deboning of broiler chickens with the production of all semi-finished poultry meat products on the bone.

| name of raw materials | Percentage of yield to weight of broiler chickens, % |

| Ham leg n/a | 33% |

| Breast n/a | 32% |

| Wing n/a | 11,5% |

| Frames (including soup set) | 22,5% |

| Technological losses | 1% |

When cutting broiler chickens, the frames could be sorted into a soup set as a ready-made semi-finished product, or chicken frames could be used for the production of mechanically deboned poultry meat.

Technological losses in a decent amount during deboning of poultry meat are due to the loss of meat juice and raw fat.

When deboning broilers, average data were obtained on the time consumption for deboning 100 kg of raw materials in the first case, the average value is 1 hour 10-20 minutes, in the second case around 1 hour.

Sincerely, Evgeniy Gorbunov.

Tags: reviews, technology, raw materials, portfolio, processing, production, meat, semi-finished products.

Did you like the article? Rate it by putting the appropriate star. Would you like to receive links to new articles by email “Subscribe to news”. Attention!!!

When quoting the text of articles and using any materials from the portal “Meat. Meat products. Food technologies." A link to the website https://foodteh.ru/ is required.

Manual technology

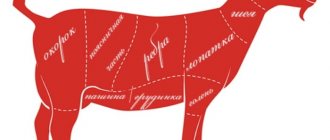

Next, begin the actual deboning of the pork. The following rules and regulations must be observed when performing this procedure:

- The shoulder, shoulder, thigh and pelvic parts of the carcass are separated in such a way as not to disrupt the integrity of the muscle mass of the meat;

- the lumbar and dorsocostal parts are cut off, observing the boundaries of the longissimus muscle, subscapularis, hem and brisket;

- the dorsal costal part is either cut off in a layer and then divided, or semi-finished products are directly isolated.

Carefully debon the pork, taking care not to damage the muscle tissue. According to the regulations, after this procedure there should be no cuts more than 10 mm deep on the meat.

Manual deboning technology for pork meat is usually used if the meat is intended for making minced meat for sale or, for example, for making dumplings. When producing sausages, half carcasses are processed using a different, simpler technology. Minced meat, since it contains more veins, in this case turns out to be of lower quality, but the labor costs when using this technique are small.

Cost of cutting

Let's take a meat cutting shop as an example. Pork and beef half-carcasses are used as raw materials. Finished products are products of cutting half-carcasses: neck, ham, ribs, etc. Do not forget that as a result of cutting, waste is also formed, for example, bones.

Let’s say half-carcass pork is supplied to our workshop for 200 rubles per kilogram. We will also significantly simplify the cutting scheme. Suppose that as a result of cutting a pork half, we end up with 30% neck, 50% ham and 20% bones. Now the question is: what is the cost of the neck and other components of the half carcass?

I have come across several calculation options in books and on the Internet. For example, some propose to install special coefficients in the TTC. What part of the cost will fall on this or that part of the half carcass? Some suggest calculating these coefficients automatically, based on the average market price of these components. Both of these methods do not work unless the half carcass is cut completely. And in most cases, the piece that is needed right now is simply cut off from the half carcass, and the rest is left “hanging until better times.” It turns out that the cutting acts do not coincide with the Third Transport Code at all. Hence the erroneous determination of cost.

Who even said that the cost of a neck should be higher than the cost of a ham, shank, or even bones? Why are all economists trying in one way or another, in different synthetic ways, to make it different?

Getting the pulp

As we have already said, meat deboning is one of the technological processes of processing raw materials, as a result of which muscle tissue is separated from bones. This work requires knowledge of animal anatomy, since knife movements must be thought out. The deboner needs to know where to point it to quickly separate the flesh from the bone.

Pork, beef, parts of poultry, lamb, and indeed any raw meat must be deboned. Carcasses and half-carcasses after defrosting, if they have been frozen, undergo this process. Special cutting tools are used for it if deboning is done manually. In large enterprises, conveyors, pneumatic tools and circular saws can be used at this stage of meat processing.

Slaughter yield of carcasses of different species of animals and birds

Of course, at first glance it seems that if a pork neck costs 350 rubles per kilogram in a store, and a knuckle costs 70, then the cost of their production should be different. But let's remember what cost is. This is the cost per unit of production. And our costs are 200 rubles per kilogram of a half carcass (for simplicity, we will neglect the wages of the hewers)!

From here we come to the conclusion that the cost of necks, shanks, bones, and lard is all equal to 200 rubles per kilogram.

Please note how easy it is to calculate income from sales of our cut. By selling a neck for 350 rubles, we receive 150 rubles in income. From selling ham we get 100 rubles in income, and by selling lard for 50 rubles we get 150 rubles in loss per kilogram. Adding up all these numbers, you can easily get income from cutting a half carcass.

Don’t rush to throw tomatoes and say that we cannot sell lard at a loss! If you dig even deeper into an economics textbook, it becomes clear that the cost of raw materials is the cost of alternative use of raw materials. What is the alternative to selling lard for 50 rubles? If you don’t sell it, but keep it in storage, you will lose those 50 rubles and earn nothing at all. Therefore, you can sell.

By the age of forty, Horland Sanders had worked as a washer, fireman, insurance agent, miner, tram conductor, and furniture loader. He didn't have a regular job or his own home, but he had a recipe for chicken fried in a mixture of herbs and spices. One day, Horland Sanders heard a humorous radio program about how “life after forty is just beginning.”

He later said that these words changed his life. Sanders opened a small auto repair shop on the side of the interstate. In the cafe at the auto repair shop, if you can call it that, a small room with one table and a few chairs, the menu was based on fried chicken dishes. This began the story of the creation of the KFC company, which now has more than 18,000 restaurants around the world, and the chicken recipe has become one of the best-kept culinary secrets in the world.

You can have different attitudes towards fast food, but it is a fact that chicken meat makes up a significant part of the meat diet in most families . What would a holiday table be without chicken baked in the oven until golden brown? Grilled wings, breasts in sauce, fried legs, and “medicinal” chicken broth? Everyone has their own favorite dish.

To produce chicken meat, poultry farms use broiler chickens, and when we buy broiler chicken meat in a store, we don’t even think about where this name came from, why this particular breed is used for breeding, and how much meat comes out of a cut broiler carcass.

Broilers are two-month-old chickens that are raised for meat. Broil translated from English means “to fry, to fry . One of the important qualities of this breed is early maturity - at the age of two months, chickens can reach a weight of up to 2.5 kilograms . The absence of dark skin and dark feathers are also important marketable qualities. After two months of age, chicken growth and weight gain slows down, and the bird must be slaughtered.

For a gutted chicken, the meat yield is approximately 60%, the bones account for 10 - 15%, in total, answering the question of how much meat comes out of a cut broiler carcass, we can talk about a value of 50% of the pre-slaughter weight of the bird . It’s not difficult to calculate that if you buy a gutted chicken weighing 1 kg, you can get 800-900 grams.

Raising chickens for meat

If broiler breeds are raised, the business is profitable. A couple of months after purchasing 30 chickens, the owner is able to obtain approximately 90 kg of dietary product. Chicks up to 20 days old give a good increase per day. To maintain growth rates after 3 weeks, it is necessary to maintain a certain humidity in the room, control the temperature and diet.

Raising young animals does not take more than 3 months - this is how long broilers grow. This is followed by slower growth and greater feed consumption. To regulate weight gain over a given period of time for chickens, it is useful to find out how much broilers need to be raised before slaughter, and how weight gain changes with age. Chicken weight gain occurs within 2 months and reaches 2-2.5 kg.

From the age of 10 days, the birds’ rational nutrition and compliance with the fattening regime are strictly monitored:

- If broilers do not reach the standard weight, the calorie content of the feed is increased. Otherwise, raising poultry is not a very profitable activity. When a large chick hatches, the weight is 50 g. A medium-sized chick weighs 40 g.

- In order for broilers to rapidly gain weight, they are fed factory-made feed. Dry food is fed to young animals for 10 days. By this time, weight gain is within 200 g.

- Proper fattening guarantees a 5-fold increase in weight in 10 days. At 14 days, the weight of the chicken is 500 g. Next, the growth of the bird is inhibited.

- Within a month after hatching, the weight of the broiler reaches 1000-1500 g. The tenderness of broiler meat will tell you when to cut the bird. 60-day-old chicks weigh 3 kg.

Meat yield from chicken when cutting

meat pulp.

By the way, in 2016, the nephew of Harland Sanders' second wife shared a secret recipe for making KFC fried chicken; according to him, he found a recipe of 11 spices and herbs in his aunt's old papers. Now everyone can try the most secret culinary recipe at home and perhaps someone will have another favorite dish on their home menu.

This entry was posted in the Poultry Meat section and tagged Bird Anatomy. Bookmark the permalink.

How to measure the weight of a broiler?

Body weight is measured at least once a week, preferably daily. The procedure is carried out at the same time, before feeding. The farmer can use steelyard, electronic or mechanical scales.

Body weight is measured at least once a week, preferably daily

Small chicks are placed in a box one at a time and a measuring device is installed on top (after weighing the container).

Schemes for cutting chickens to obtain natural semi-finished products

DS.03 TECHNOLOGY OF SEMI-FINISHED MEAT PRODUCTS

Practical lesson. Study of poultry cutting schemes for the production of semi-finished meat products

METHODOLOGICAL INSTRUCTIONS

Specialty 260301 Technology of meat and meat products

Ufa 2006

UDC 637

BBK 36.92

P 69

Recommended for publication by the methodological commission of the Faculty of Food Technologies (protocol No. 3 of October 25, 2006)

Compiled by: Art. Rev. A.R. Salikhov

Art. Rev. AND I. Gizatov

Reviewer: Associate Professor of the Department of VSE, Ph.D. A.M. Galiullina

Responsible for release: head. Department of TMM, Ph.D.,

prof. A.V. Savelyev

Ufa, BSAU, Department of Meat and Milk Technology

Purpose of the lesson: To study the schemes for cutting poultry carcasses to obtain semi-finished meat products.

Tasks:

— study the scheme of cutting chicken carcasses to obtain packaged meat and natural semi-finished products;

— study the scheme for cutting broiler chicken carcasses to obtain packaged meat and natural semi-finished products;

— study the scheme for cutting up waterfowl carcasses to obtain packaged meat and natural semi-finished products;

— study the scheme for cutting turkey carcasses and turkey poults to obtain packaged meat and natural semi-finished products

General information

For the production of semi-finished poultry products, carcasses of chickens, ducks, geese, and turkeys are used; for quick-frozen ready meals - chicken carcasses. Depending on the age of the bird, meat is divided into meat of young and adult birds. Young poultry meat includes the carcasses of chickens, broiler chickens, ducklings, goslings, and turkey poults with a non-ossified (cartilaginous) keel of the sternum, a non-keratinized beak, and soft plastic skin on the carcass.

On the legs of chicken carcasses, broiler chickens, and turkey poults there are smooth, dense, adjacent scales and spurs that are not developed in the form of tubercles; There is tender skin on the legs of ducklings and goslings. Adult poultry meat includes carcasses of chickens, ducks, geese, and turkeys with an ossified (hard) keel of the breastbone and a keratinized beak.

The young bird has a flexible, smooth, brightly colored crest with a pointed end. Ducklings have a flexible beak. An adult bird usually has a darker color, a rougher body, the end of the keel is dense, without cartilage.

Semi-gutted and gutted carcasses are supplied for the production of semi-finished products and ready-made quick-frozen poultry meat dishes. In semi-gutted carcasses, the intestines with the cloaca, the filled crop, and the oviduct (in females) have been removed.

Broiler growth and nutrition

The nutrition of broiler chickens depends on the age and fattening stage at which the bird is.

The following periods are distinguished:

| Phase | Age, days | Feed rate, grams | Products |

| Prestart | 0-5 | 15-20 | Millet, oats, boiled eggs, semolina, barley. Most of the feed is grain |

| Start | 6-18(up to 30) | 25-90 | Grain, boiled egg, chopped greens, grated carrots and pumpkin, peas, soybeans, cottage cheese, corn, wheat, curdled milk, milk, vitamins |

| Fattening | 19-37(up to 60) | 90-160 | Add chalk, boiled potatoes, fish, bone meal, bread yeast |

| Finish | 38-90 | 160-170 | They are fed solid food using the products already listed. Protein is removed, the volume of greens is significantly increased |

The frequency of feeding also depends on age.

Sometimes the growth of a bird’s body weight is delayed

You must adhere to the following frequency:

- 1 week – 8 times a day;

- 2 week – 6 times daily;

- 3 week – 4 times a day;

- 4 weeks until slaughter – twice a day.

Compound feed used in feeding can be in the form of dry granules of various fractions, or wet, when all products are soaked in milk, broth or whey.

The volume of liquid consumed in relation to feed is 1.7:1. It is recommended to feed the bird a solution of potassium permanganate to prevent gastrointestinal diseases.

Meat yield

Gutted carcasses have all internal organs removed, the head (between the 2nd and 3rd cervical vertebrae), neck (without skin) at the level of the shoulder joints, legs up to the tarsal joint or below it (but not more than 20 mm). The internal fat of the lower abdomen remains on the carcass. Usually the lungs and kidneys remain on the carcasses.

Depending on the temperature in the thickness of the pectoral muscles, poultry carcasses are divided into cooled (temperature no higher than 25 ° C), chilled (temperature from 0 to 4 ° C) and frozen (temperature no higher than –8 ° C).

Based on fatness and carcass processing, birds of all types are divided into two categories: first and second. The fatness of a bird is determined by the state of the muscular system (muscle development) and the presence of fat deposits on the surface of the carcass. The quality of poultry processing is assessed by the degree of feather removal (cleanliness of processing), the condition and type of skin, and the condition of the skeletal system. Poultry carcasses that meet the requirements of the first category in terms of fatness, and the requirements of the second category in terms of processing quality, are classified as the second category.

Carcasses of the first category of all types of poultry have well-developed muscles, the chest is round in shape, the keel of the breast bone does not stand out, with the exception of carcasses of chickens and turkey poults. Deposits of subcutaneous fat on the carcasses of adult birds are on the chest, belly and back; on the back of chicken and turkey carcasses - in the form of a continuous stripe, on geese carcasses - significant, including under the wings, on broiler chicken carcasses - insignificant in the lower abdomen (in addition, on chicken carcasses - in the form of an intermittent stripe on the back) , on the carcasses of ducklings and turkey poults - on the chest and belly.

Carcasses of the second category of all types of poultry have satisfactorily developed muscles, the chest is angular in shape, the keel of the breast bone can stand out; There should be slight deposits of fat in the lower abdomen and back, but may be absent if the muscles are satisfactorily developed.

Poultry carcasses that do not meet the fatness requirements of the second category are classified as lean.

Each bird carcass is marked with electromarking. The mark (for the first category - number 1, for the second category - number 2) is applied to the outer surface of the leg: for chicken carcasses, broiler chickens, guinea fowl, hens, ducklings, guinea fowl - on one leg; for carcasses of ducks, goslings, geese, poults and turkeys - on both legs. Poultry carcasses subject to industrial processing are marked with a “P” electrical mark on the back. The height of the numbers and letters of the stamps is 20 mm.

The transport container must have a stencil or label indicating the manufacturer, subordination, trademark, symbol of the type of poultry, category and method of processing poultry carcasses, number of carcasses, net and gross weight, date of production and designation of the standard.

Symbols for poultry carcasses. By type and age: chickens - C, broiler chickens - CB, hens - K, ducklings - UM, ducks - U, goslings - GM, geese - G, turkey poults - IM, turkeys - I, guinea fowl - SM, guinea fowl - C .

By processing method (after the symbol of the type of bird): semi-gutted - E, gutted - EE, gutted with a set of giblets and neck - R.

By fatness (after the symbol of the processing method): first, category - 1, second category - 2; not corresponding in terms of fatness of the first and second categories (skinny) - T. Containers of poultry meat sent for industrial processing

Schemes for cutting chickens to obtain natural semi-finished products

Chicken meat is used to produce: chicken fillet with bone; chicken leg; chicken broth set; chicken carcass prepared for cooking (Table 1).

To produce semi-finished products from chicken meat, gutted and semi-gutted carcasses of chickens of categories I and II are used, chilled and frozen, with a shelf life in a refrigerated state of no more than 3 days, in ice cream - no more than 2 months.

Table 1 – Assortment and characteristics of natural semi-finished chicken meat products

| Semifinished | Characteristics of the semi-finished product | Portion weight, g |

| Carcass prepared for cooking | Gutted carcasses from which the wings up to the elbow joint, part of the skin, lungs and kidneys have been removed. Internal fat has been removed. The site of neck separation is covered with a piece of skin tucked into the hole formed after removal of the goiter, trachea and esophagus. The tarsal joints are tucked into pockets. Skin surface without stumps and hair-like feathers | Product by weight |

| Fillet | The pectoral muscles are oval in shape with a superficial film, without skin. The tendon between the major and medial muscles was cut two or three meters away, and it was removed from the minor muscle. The edges are smooth, without deep cuts. | 250, 500 or from 200 to 1000 |

| Fillet with bone | The pectoral muscles are oval in shape with a superficial film, without skin, with a humerus bone 3-4 cm long freed from pulp and a chopped off part of the head of the shoulder joint. The tendon between the major and medial muscles was cut two or three meters away, and it was removed from the minor muscle. The edges are smooth, without deep cuts. | 250, 500 or from 200 to 1000 |

| Ham | A part of a carcass consisting of the femur, tibia and fibula with adjacent muscles and skin. Skin surface without stumps and hair-like feathers | 250, 500 or from 200 to 1000 |

| Broth set | The part of one or more carcasses remaining after the separation of fillets and legs, including trimmings from the processing of fillets and fillets with bone. The surface of the skin of the remaining parts is without stumps and hair-like feathers | 500, 700, 1000 or from 200 to 1000 |

To obtain natural semi-finished products, chicken carcasses are cut according to the scheme presented in Figure 2.1. At the same time, there are two options for selecting carcass parts to obtain natural semi-finished products:

– in the first case, the breast, quarters, and soup set are isolated;

- in the second - breast, legs, soup set.

Yield rates for these cutting options are presented in Table 2.

But it should be taken into account that the given cutting schemes are not the only possible ones and used at all poultry processing enterprises. There are many ways to cut chicken carcasses, mainly differing from each other in the different set of separated parts and their percentage in the total mass of the carcass.

One of these options for cutting and isolating natural semi-finished products from chicken carcasses is presented in Table 3.

Figure 2.1 Cutting chickens to obtain natural semi-finished products: A-A - line for separating the dorsal-scapular part; B-B - line of division of quarters; 1 - breast; 2 - legs; 3 – dorsal part; 4 – wings

Table 2 - Names of natural semi-finished products and their yield from chicken carcasses

| Name of carcass parts | Yield of parts, % of carcass weight | |

| Method I | II method | |

| Breast | 23,4 | 25,4 |

| Ham | — | 33,7 |

| Quarter | 49,2 | — |

| Soup set | 26,4 | 39,9 |

| Technological losses | 0,7 | 0,7 |

| Technical waste | 0,3 | 0,3 |

Table 3 - Names of natural semi-finished products and their yield from chicken carcasses with an alternative cutting option

| Part name | Yield rate, wt.% carcasses | Assortment of semi-finished poultry meat products |

| Fillet | 22,3 | skinless fillet, escalope, goulash, stew |

| large fillet | 17,5 | large fillet |

| small fillet | 4,8 | small fillet |

| Ham, including: | 29,5 | ham, ham crote, goulash, stew |

| shin | 15,7 | drumstick, drumstick crote, stewing meat |

| hip | 13,8 | thigh, thigh crote, entrecote |

| Chicken wing, including: | 12,6 | wing (whole) |

| shoulder part of the wing | 6,1 | shoulder part of the wing |

| ulnar part of the wing | 6,5 | ulnar part of the wing |

| Broth set | 32,5 | quarter (hind), chicken tail |

| Neck skin | 2,1 | neck skin for stuffing |

| Technological losses | 0,7 | |

| Technical waste | 0,3 |

Calculation of cost in proportion to the selling price

In the latest versions of Mercury-ERP, a mechanism has appeared for calculating the cost of production in proportion to the consumable price of the product. This scheme is described in detail in the video:

- Workshops and areas

- Raw materials, semi-finished products and finished products

- Technical and technological maps in production

- Production plan

- Product cost calculation

- Cost of cutting

- Traceability. Traceability.

- Accounting at a meat processing plant. Automation of a meat processing plant.

- Production act

- Accounting in clothing production.

Manual deboning of poultry carcasses is an extremely labor-intensive operation (even skilled workers deboning no more than 100 kg of poultry per shift). In addition, it is generally impossible to more or less completely separate the meat from the bones by hand. When mechanically deboning the dorsal-scapular part of poultry carcasses and wings on screw-type presses, the meat yield is on average 60-65%, while during manual processing no more than 20-25% of pieces of meat are separated from this part. The use of mechanical deboning equipment for beef and pork almost always requires a business case due to the low bone content and often low production volume. As for mechanical deboning of poultry meat, even with small output volumes (for example, 200-300 kg/h) it provides noticeable profits. However, it should be borne in mind that manual and mechanical deboning of poultry carcasses produces raw materials that differ significantly in consumer and nutritional value. With manual deboning - fillet (white meat from the breast part of the carcass), large and small pieces of meat, with mechanical deboning - skin, fat, meat. The quality of these parts of the bird can be compared using grading coefficients, which were first given in TU 9214-301-23476484-98 “Semi-finished chicken meat products. Cutlets, schnitzel, galantine.” When choosing the numerical values of the coefficients, we took into account the technological possibilities of using each type of raw material to obtain different products (for example, natural and chopped semi-finished products), their nutritional value (ratio of protein, fat, water), consumer value (it was determined by retail prices in stores and on wholesale markets in Moscow) and, of course, taste. The table shows comparative characteristics of cutting broiler carcasses with manual deboning of the entire carcass and mechanical processing of the dorsal-scapular part and wings. Yield indicators and grading factors for various parts of carcasses are not mandatory for calculating the cost of poultry products. But they give a relatively accurate and practice-tested ratio of the cost of products.

| Yield standards and grading factors for raw materials when cutting broiler chicken carcasses Average yield % weight of gutted poultry | |||

| manual mechanical | Grade factor | ||

| Fillet (premium grade) | 16 | 16 | 1,5 |

| Large pieces of meat from the chest and thigh parts (1st grade) | 17 | 17 | 1 |

| Small pieces of meat from the chest and thigh parts (2nd grade) | 14D | 14,1 | 0,9 |

| Skin and fat | 22,1 | 22,1 | 0,6 |

| Wings | 4,6 | — | — |

| Bones | 24,1 | — | |

| Raw materials for mechanical deboning | — | 28,7 | |

| Mechanically separated meat | — | 18,7* | 0,8 |

| Bone remnant | — | 9,7 | — |

| Unaccounted losses | 2,1 | 2,4 | — |

| Total raw materials for the production of semi- | 66,8 | ||

*The yield of mechanically separated meat based on the mass of raw materials is assumed to be 65%. The production of chopped semi-finished products, especially at small enterprises, has reached noticeable volumes and continues to grow, bringing tangible profits. Labor productivity during mechanical deboning of poultry meat increases many times over. But if you debone whole carcasses, as is often done, then you should keep in mind a decrease in the overall quality of the resulting raw materials. Mechanically separated meat has significantly lower consumer value. It is a finely ground mass, which, compared to hand-boned meat, has less protein, more fat and a worse taste. During the deboning process, as a result of compression and destruction of bone tissue, bone marrow fat with a high content of phospholipid compounds, unstable during storage, and small pieces of bones pass into the meat fraction. With stronger compression of meat in the separating head, its yield increases. This is accompanied by an increase in the number of bone particles and their size. In addition, with strong compression, the separating head of the press wears out much faster. Due to the sensation of bone particles when chewing the product and the less pronounced taste of mechanically separated meat, it is advisable to introduce components into the recipe that neutralize these shortcomings. These products include primarily pork, beef, and hand-boned poultry. In general, as experience shows, when up to 30% of mechanically separated meat is added, the taste qualities of meat products remain as high as when made only from manually separated meat, pork, and beef. Combined deboning of carcasses is optimal: the chest and thigh parts of the carcasses are manually separated, and the dorsal-scapular part, wings and necks are separated mechanically. When using special devices - a cone for cutting poultry carcasses and a device for deboning chicken legs - labor productivity per worker, including personnel involved in packaging semi-finished products and loading and unloading operations, reaches 200 kg of finished product per shift. Large pieces of meat from the breast and thigh parts (fillets of white and red meat, respectively) obtained by hand deboning the carcass can be used to produce natural products: Kiev cutlets, natural chicken schnitzels (TU 9214-404-23476484-01), stuffed chicken legs (TU 9214-313-23476484-99), immediately (TU 9214-316-23476484-00).

From small-piece raw materials and mechanically separated meat, chopped semi-finished products can be produced: cutlets, schnitzels, meatballs, zrazy, meatballs, lula-kebabs, the main difference of which is the shape. The production of poultry meat relatively often and in large quantities is azu (finely chopped pieces), galantine (a roll wrapped in skin), beef stroganoff (small oblong pieces), frying (small pieces of boneless meat), stew (small pieces of meat on the bones), fillet (a whole piece from the breast or leg part of the carcass), shish kebab (pieces of chicken meat with or without bone). Provided there is good market demand for natural semi-finished products (legs, breasts, wings and necks), only the dorsal-scapular part of the carcass is deboned. In this case, in principle, a combined cutting of the carcass is carried out. Legs, breasts, wings and necks are sold in the form of natural semi-finished products (TU 9214-310-23476484-01 and TU 9214-313-23476484-99), the rest after mechanical deboning - in the form of minced meat or used to produce chopped semi-finished products. It is less economically profitable to sell mechanically separated meat in the form of minced meat than chopped semi-finished products. But since it is more difficult to organize the production of the latter, meat is often sold in the form of minced meat.

Slaughter weight

Slaughter weight (weight) in cattle is the weight of the carcass without skin, head, entrails and lower parts of the legs.

The slaughter weight for sheep is the weight of the carcass without entrails and lower parts of the legs, and for pigs without bristles.

In poultry, the slaughter weight depends on the characteristics of the post-slaughter processing of the carcass: in uneviscerated poultry it is the highest, since it includes the weight of the bloodless and plucked carcass with fat, head, legs and internal organs; for semi-gutted - the mass of the carcass with fat, but without intestines; with complete evisceration, not only blood, feathers, fluff and intestines are removed; but also all internal organs, also the head to the second cervical vertebra, legs to the tarsus and wings to the elbow joint.

Extracting the insides correctly

Step by step

You need to gut the chicken as quickly as possible after plucking. So that leftover food in her gastrointestinal tract does not begin to rot and ferment. This will give the meat an unpleasant smell and taste.

We start by removing the intestines. Hold the tail with one hand. And insert the second one into the hole at the bottom of the carcass and grab the intestine. Pull carefully so as not to tear it.

Next, you need to cut out the stomach and liver of the bird. Cut the places where they connect to the body with a knife. Try to get the spleen, gall bladder and liver together. And separate them from each other on the board. If you damage them, you will ruin the meat.

Now take out the esophagus and larynx. If this was not possible when extracting the goiter. Then cut out the internal genital organs: ovaries for chickens, testes for roosters.

Final stages

Lastly, the lungs and heart are removed by cutting the adjacent vessels and tissues.

The gutted carcass must be washed. Clean from fat. The stomach is turned out, an incision is made, and any remaining food is removed. Remove the inner layer of skin.

You can use a fork for gutting. Once the intestine has been removed, insert it into the hole and cut the tissue to which the innards are attached. Turn the bird over and the giblets will fall out.

Now proceed directly to cutting the chicken carcass, the rules of which we will describe below.

Cutting chicken: schemes, standards, technologies

They have increased early maturity, well-developed and fine-fiber muscles with desirable layers of fat, which give the meat juiciness and tenderness.

Rabbits are slaughtered in November-December after molting, when the hair becomes thick and shiny. Pre-slaughter fasting should be 12 hours with plenty of water provided. The most optimal age for slaughtering rabbits of all breeds is considered to be 110-130 days old, except for black-brown and gray giants. They are kept for up to 160 days.

When slaughtering chickens , ducks , geese , turkeys , the bird is taken by the head and the throat is cut 1.5-3 cm below the earlobe or ear (in waterfowl). The duration of bleeding is 1.5-3 minutes. Removing the feather and down covering from carcasses is very difficult. Thus, when processing poultry manually, labor costs for removing feathers account for 80% of all labor costs for processing the carcass. The quality of the carcass is directly dependent on the thoroughness of feather removal. If there are rips and scratches on the carcass, then the grade of such carcass is reduced regardless of its fatness. When removing feather cover, they also take into account the need to preserve the quality of the feather itself, especially down, which is a valuable raw material for the manufacture of various feather and down products.

The slaughter yield of chickens, geese, ducks and turkeys is 57 - 60%, and half-gutted 77 - 80%

Average slaughter yield of animals of different species

| Animal species | Slaughter yield % |

| Cattle | 55-66 |

| Sheep | 44-52 |

| Pigs | 75-85 |

| Horses | 47-52 |

table - average slaughter yield of animals

Indicators of slaughter and meat quality of bulls of different breeds (age 18 months)

| Breed | Simmental | Red Pied | Kazakh white-headed | Red steppe | Black and white | Kalmytskaya |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Weight on farm, kg | 522,6 | 487,1 | 464,8 | 451,1 | 462,7 | 419,6 |

| Weight at the meat processing plant, kg | 514,3 | 479,8 | 455,1 | 442,4 | 454,4 | 407,9 |

| Transportation losses, kg | 8,3 | 7,3 | 9,7 | 8,7 | 8,3 | 11,7 |

| Carcass weight, kg | 278,6 | 253,5 | 253,5 | 235 | 236,4 | 222,3 |

| Carcass yield, % | 54,2 | 52,8 | 55,7 | 53,1 | 52 | 54,5 |

| Internal fat mass, kg | 12,1 | 10,7 | 13,2 | 11,5 | 8,7 | 12,3 |

| Yield of internal fat, % | 4,3 | 4,2 | 5,2 | 4,9 | 3,7 | 5,6 |

| Slaughter weight, kg | 290,7 | 264,2 | 2bb,7 | 246,5 | 245,2 | 234,7 |

| Slaughter yield, % | 56,5 | 55,1 | 58,6 | 55,7 | 54 | 57,5 |

| Internal fat yield relative to carcass | 4,3 | 4,2 | 5,2 | 4,9 | 3,7 | 5,6 |

table - indicators of slaughter and meat quality of bulls of different breeds

Meat qualities of pigs of different breed combinations

| Item no. | Breed combinations | Pre-slaughter weight, kg | Area of the muscle eye, cm2 | % fat | % meat | % bones | Meat index | Lean index |

| 1 | T | 100,5 | 43,7 | 18,3 | 69,05 | 12,65 | 5,46 | 3,77 |

| 2 | KBhLn | 100 | 49,1 | 22,9 | 64,1 | 12,75 | 5,02 | 2,79 |

| 3 | (KBxLn)D | 100 | 45 | 24 | 64,3 | 11,65 | 5,5 | 2,68 |

| 4 | (KBxLn)xPt | 100 | 51,1 | 28,25 | 60,85 | 10,75 | 5,66 | 2,15 |

| 5 | (KBxLn)xT | 101 | 50,5 | 25,5 | 64,6 | 9,9 | 6,5 | 2,53 |

| 6 | (KBx D)x Ln | 99,5 | 53,55 | 23 | 65,9 | 10,85 | 6 | 2,86 |

| 7 | (KBxD)xPt | 103 | 54,9 | 22,2 | 66,1 | 11,7 | 5,65 | 2,98 |

| 8 | (KBxD)xT | 101,5 | 50,85 | 19,4 | 68,8 | 11,8 | 6,19 | 3,55 |

| Average | 100,8 | 49,8 | 23 | 65,3 | 11,6 | 5,6 | 2,84 | |

table of meat qualities of pigs of different breed combinations

Slaughter yield of rabbit meat depending on age, %

| Breed | Age, days | |||

| 65 | 110 | 135 | 270 | |

| White giant | 46,2 | 53,2 | 59,8 | 60,0 |

| Gray giant | 45,4 | 53,4 | 59,2 | 59,1 |

| Black-brown | 46,4 | 52,3 | 57,5 | 57,9 |

| Silver | 51,5 | 54,9 | 58,6 | 53,1 |

| Vienna blue | 50,8 | 53,4 | 56,6 | 61,2 |

| Soviet chinchilla | 49,8 | 51,5 | 55,2 | 59,2 |

When and how to cut broilers

The owner of the farmstead decides independently when to chop broilers. Weight gain in broilers is the starting point for slaughter. Domestic broiler chickens are often slaughtered at 80 days of age when they reach at least 2.5 kg. Raising chickens for a longer period is unprofitable. The bird grows faster in the first month, then development slows down.

Before slaughtering broilers, preliminary preparation is carried out:

- Antibiotics are prohibited 3 weeks before slaughter.

- Fish waste, minced meat, and gravel are excluded from the diet for 12 days.

- Immediately before slaughter, chickens are kept on a fast ration for 12 hours, this does not apply to water. Fasting is carried out during the daytime to allow the digestive organs to function as usual. Otherwise, the remnants of indigestion and waste from the excretory system will end up inside the carcass and spoil the taste of the meat.

- To preserve their presentation, individuals are held by their paws. When the wing is picked up, bruises appear. When catching, act carefully to avoid injury to the belly and wings.

On a note. Obtaining liquid Glauber's salt activates the processes of cleansing the stomach of birds.

Device for slaughtering broilers

When slaughtering boilers, a practical device is used, which allows for quick and humane preparation of the carcass. The device will help you how to cut broilers and other birds at home.

To make a tool, you do not need to purchase expensive materials - all the required building materials can be easily found in the farmstead.

Broiler slaughter cone

Suitable for manufacturing:

- unusable bucket;

- roofing sheet trim;

- 3 liter plastic bottle.

To make a cone, the drawings or patterns fit.

Cone according to drawing

When making a mechanism for slaughtering broilers, they take into account the size of the birds.

The instrument drawings represent a model of a truncated cone from an eighth grade geometry textbook. Inserting the required dimensions will allow you to obtain individual measurements for a workpiece made of 0.4-0.5 mm sheet iron.

They use another technique, which is simple and quick:

- make a paper bag that is the same size as the cone;

- a chilled carcass is suitable as a sample;

- the broiler easily fits into the hole at the top of the funnel;

- the required dimensions are marked on the bag;

- excess areas (overlap and the lower part of the cone) are cut off;

- the opening from below is made for the head of a large broiler in the poultry house;

- unfolding the bag creates a drawing of the planned product.

Cutting in different ways

The first method is classic

First, the legs are separated by cutting the skin around them from the belly to the back. Then the wings are cut off in the same way. The breastbone is cut off from the back, focusing on the fold of fat on the side of the carcass.

Then the fillet is removed from the breast. The skin and flesh are cut near the neck and at the cartilages. Using your hands and a knife, separate the meat from the bones. The fillet can be cut or left whole.

Second method: in half

Cutting chicken into half carcasses. The carcass is cut in half from the keel and along the spine. Then the meat is removed from the breast. The bone is cut out and the spine is separated. The output will be two equal parts and broth bones.

The third method - for 8 pieces

First, divide the chicken into half carcasses. Then cut a leg from each. Cut each piece into 2 parts - thigh and drumstick - dividing along the joint. Separate the wings from the breast.

The fourth method is waste-free

It is called so because it leaves no unnecessary bones.

The scheme is this: we do everything as in the classic version. But we cut the back left after removing the fillet from the breast in half. If necessary, cut the ribs from the backbone.

Fifth method - portioned pieces

Place the carcass on its back. Separate the legs. And then thigh from shin. Make two vertical cuts along the sternum and spine - divide the carcass in half.

We cut each piece into two more pieces horizontally. You will get 8 equal parts. Cutting chicken beautifully into portioned pieces will not work the first time. It's important to get the hang of it.

How to remove the skin from a carcass

It's useful to know more than just how to cut up a chicken. But also how to remove the skin from it for later use.

Place the carcass on its back with the bottom hole facing you. Separate the breast skin from the meat using a knife or your hand. Turn the bird over and use kitchen scissors to trim the connective tissue to remove the skin from the back.

Cut through the joints of the legs and wings. Separate the skin from the main carcass. And remove it from your feet with a “stocking.” To prepare the roll, the wings and legs are separated at the second joint. And for stuffed chicken, you can leave them completely.

Tips from chefs

Nuances

The carcass must be fresh. Thaw frozen chicken completely, rinse and dry. Use large knives to cut larger pieces. For removing meat from bones - small, with a thin blade. Serrated kitchen scissors will help you properly divide the carcass into pieces.

Wash your hands before and after handling meat. Wash tools with hot soapy water when finished. The cutting board cannot be used to cut other foods.

Recommendations

To make the dishes look beautiful, cut off the last phalanges (tips) of the wings. Pre-removing the tendons from the fillet will help make the finished chicken softer.

Store raw meat in the freezer separately from vegetables and fish. So that it cannot become saturated with their smells. For the same reason, raw poultry is kept on the bottom shelf in the refrigerator.

It is important to cut the chicken into pieces properly. And cook each part correctly to maximize the flavor. You can stuff the bird with vegetables, which are cut into pieces of different sizes, cereals, potatoes, cheese mixed with other ingredients.

Raw meat and its characteristics

For the production of semi-finished products, sausages and packaged products in Russia and Ukraine, beef, pork, chicken and, less often, lamb, horse meat, goat meat, and venison are most often used.

Meat is a collection of bone, muscle, connective, fatty and nervous tissues, as well as blood and lymphatic vessels. Its components are proteins, fats, minerals and water. Due to the presence of proteins in it, the product has high nutritional value, so proper deboning of the meat is very important, when the standing pulp is preserved as much as possible when it is separated from the bones.

Each type of meat has a different tissue ratio, for example, pork has a higher percentage of fat than beef. In general, the chemical composition of the product is influenced by the breed, age, sex and fatness of the animal. A small amount of fat in meat increases the value of the product. Thus, the most delicious piece is considered to be marbled meat, the muscle fibers of which have a fatty layer.

Safety precautions

Boning meat requires caution and compliance with labor safety instructions on the part of the worker. The danger lies in possible cuts during manual cutting and electric shock during mechanical deboning.

For example, when working with a knife for himself, a deboner runs the risk of getting cuts on the stomach while cutting up a carcass. When deboning the scapula, neck, or stripping the pelvic part, when the thumb and forefinger of the left hand go deeper into the meat, there is also a possibility of damage to the limb.

Therefore, the worker must be provided with certain protective equipment:

- an apron;

- chain mail and cotton gloves;

- boots;

- helmet;

- oversleeves.

Thus, a two-fingered metal glove is designed to protect the left hand, and a chain mail apron or apron ensures the safety of the body.