Having decided on the number of pigs to be bred and the purpose of keeping them, you can begin to design and build a pigsty. Available standard drawings and instructions will help with this, following which it will be possible to build a clean, dry and spacious room with good lighting, where animals will feel completely safe and comfortable.

Preparing to build a pigsty

Before you start designing, let alone building, you should decide on the general concept of the pigsty. It is necessary to decide in advance not only how many animals will be in the barn, but also what technology for keeping them the farmer will use. For example, will it be just fattening of purchased young stock, or will it be planned to create your own breeding stock, will it be planned to automate work processes, or will you do everything by hand?

The answers to these questions will greatly influence the size of the pigsty, its layout and technical equipment. After all, the raised young animals must be kept separately from the queens and piglets, which in turn require special conditions of detention. And the use of automatic systems for waste removal and feed distribution will require a specific building layout, which is completely different from when performing these works manually.

In view of the above, before you start building a pigsty, you should do the following:

- study the most popular projects, taking into account the planned livestock and technological processes;

- choose the optimal location for construction;

- develop a building plan that takes into account all of the above factors.

Do not forget to coordinate the construction with all interested government services and institutions - BTI, SES, tax, etc.

Premises requirements

To properly design such a structure, it is necessary to take into account a number of rules:

- Before going to the pigsty, you can organize a platform with a canopy for walking animals. It should be spacious so that there is about 10 square meters per head. m. When keeping 10 heads, its optimal area is about 100 sq. m.

- Provide space for the installation of drains through which all waste will be discharged.

- The sow pen should be located away from cold walls so that the newborn offspring is warm and comfortable.

- The walls of the pens must be made higher than the height of the animals. The optimal level is 180-190 cm. Their normal depth is 2.5-3 m, however, in conditions of limited space, the machines can be made less deep, positioned only on one side, so as not to make a passage.

Experienced farmers do not make many pens of different sizes, but organize 2 pens - 3x4 m in size for keeping the entire livestock and 4x4 m in size for fattening.

- If you plan to build not one, but several machines, be sure to provide a passage between them with a width of at least 1.5 m.

- Equip the walls with 1-2 windows, but no more, since too bright lighting will disturb the animals. To organize moderate lighting in a pigsty for 10 heads, you will need 2 medium-sized windows.

- To preserve internal heat, especially in harsh climatic regions, reinforce the walls with insulation and a layer of vapor barrier.

- Pay special attention to the floor so that it is both warm and durable.

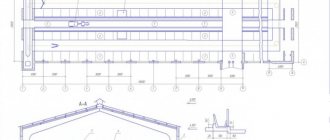

Having decided on the dimensions and layout of the pigsty, you need to prepare its drawing. Here are diagrams of two-row rooms with different numbers of passages - from one to three:

Pig sty project

If you are planning to build a small pigsty with your own hands, literally for 2-10 animals, then you can start drawing up the project yourself. But it is better to entrust the design of a larger structure (for several tens or even hundreds of pigs) to specialists. Especially if you are not a professional builder or architect.

You need to start designing not with sketches and drawings, but with determining an approximate construction estimate. The whole process inevitably comes up against this very question. It depends on him whether you have enough money for a state-of-the-art automated pig farm for 200 sows, or whether everything will be limited to a wooden two-person barn made from boards stolen from a neighbor.

If you are sure that in any case you will be able to get the amount necessary for construction, then you can start calculations by determining the number of livestock. And then bring everything else under this parameter.

You also need to remember about the norms for calculating the area per animal. Of course, in the end, it is up to you to determine whether the pigs will walk around the spacious enclosures like kings, or whether they will be content with a minimum of comfort. In any case, you should not make the room more crowded than required by objective standards for pigsties. As a rule, pigs are kept in small pens. The area standard for them is as follows:

- boars (male breeders) - one animal in a pen with an area of 8 square meters. m.;

- sows at an early stage of pregnancy - 3-4 animals per pen, 2-3 square meters each. m for each;

- sows in late pregnancy - 1-2 animals per pen, 4-5 sq. m per animal;

- sow with piglets - alone in a pen with an area of 7-8 square meters. m;

- fattening piglets (without a sow) under 5 months - 10-12 per pen, 0.5 sq. m on the head;

- fattening piglets over 5 months - 15-20 per pen, 0.7-1 sq. m per animal.

The indicated figures are the minimum acceptable, that is, if possible, it makes sense to give the pigs a little more space, but in no case less.

Also, we should not forget that in addition to pens with animals, a significant part of the premises in the pigsty building will be occupied by technological passages and blocks. Their area will depend, among other things, on how automated your pig farm is.

It is recommended to make the outer walls of the pigsty within 1.6-1.8 m, and the ceilings - no higher than 2.2-2.6 m from the floor.

Carrying out finishing work

In order not to miss important details during the interior arrangement of the room, this process should be divided into several parts.

Lighting

Natural lighting in conditions of short daylight hours will not be enough to satisfy the pigs’ need for light, on which the biological processes in their body depend. So, it is necessary to organize artificial lighting of the room. When laying wires and installing lamps, you need to assume that one 60 W lamp illuminates 3 square meters well. m.

Breeding sows with piglets need an 18-hour daylight period with illumination of about 15 lux, and for fattening animals a 12-hour day with illumination of 5-8 lux is sufficient.

Ventilation

The pigsty must be equipped with a ventilation system, following the following instructions:

- Place large-diameter exhaust pipes (40-50 cm) almost under the ceiling at the rate of 2 pieces per 10 heads.

- Equip supply openings 20 cm above the floor.

- Install dampers (discs for opening and closing the opening) on the pipes, and dampers in the form of metal gratings on the supply openings.

- Additionally, install fans in the supply openings. They should only be turned on in the hottest weather.

The operation of such ventilation is based on the principles of natural circulation of air masses: warm air rises upward and is expelled, and cold air enters from below and fills the vacant space.

Some people neglect the implementation of special supply channels, believing that windows can also perform their functions. This is not the best solution - the windows in the pigsty are located quite high, so they will not circulate air below, where the pigs are directly located.

Heating

In temperate climates, a pigsty can be built without additional heating, since the animals contained in it generate a sufficient amount of heat. The main thing is to properly insulate the room.

In areas with a harsh winter season, it is still worth organizing additional heating of the room. This can be done using air heaters, stoves or any other possible heating. It is also worth providing special heating lamps for piglets.

Machine tools

The inside of the pigsty can be fenced off using two types of materials:

- edged board 5 cm thick and timber for racks made of hard trees;

- metal pipes, sheets, corners.

The height of such partitions is about 1 m. A separate entrance must be provided for each pen. The gates must close well, so simple bolts should be additionally counterfeited with snouts.

How you can set up a pig barn with your own hands is described in the following video:

When breeding pigs, you first need to decide where they will be kept. For them, a farmer can build a pigsty with his own hands, having previously calculated its optimal size based on the number of heads in the herd. In this case, you can use various materials and technologies, so everyone can choose the option that meets their requirements and financial capabilities.

0

0

Copy link

Pig barn diagram and materials

There are many typical pigsty layouts, each of which has its own advantages and disadvantages. Most often, farmers choose one of three designs:

- two rows of machines along the outer walls and a technological passage in the center;

- two rows of machines facing each other and two technological passages along the external walls;

- The diagram is from point “b”, but the rows of machines are separated by a third central passage.

Based on data on the internal area, the height of the walls and the layout of the pens, preliminary calculations of the required amount of building materials can be made. It is also up to you to decide which materials to choose. There are no strict restrictions in this matter, the main thing is that the pigsty room is warm in winter, not hot in summer, and can be easily disinfected.

When building walls, preference is most often given to stone or brick, but small farmers can even get by with a wooden structure. In addition, you can use modern technologies - sandwich panels on a steel frame.

The foundation and floors will require large volumes of cement-sand mixture. At the same time, moisture insulation can be ensured using ordinary roofing material. There is also no point in covering the roof with tiles or sheet metal. Slate will do just fine.

The interior of the pigsty is usually lined with hardwood planks. Many farmers use metal gratings to delimit space. But keep in mind that such a lattice must be strong so that the animals do not break it and then, firstly, do not scatter throughout the barn, and secondly, do not get injured by the protruding ends of the torn out rods.

How to make a pig pen

Briefly about the nuances of constructing a summer enclosure. To build it for several individuals, wooden boards made of hardwood (for example, cedar), nails and wooden posts are useful. Select sizes according to the size of your pets. Deepen the pillars into the ground 20–40 cm, then nail boards to them.

The gaps between the boards and stakes directly depend on the size of the animals. The fence must be durable enough to support the weight and strength of the pigs. If financial capabilities allow, it is advisable to use metal poles instead of wooden blocks. Galvanized mesh panels are also ideal for fencing.

Did you know? Piglets need a piglet to loosen the soil in order to look for food in the ground.

The overall size of the pen will depend on how many pigs you have. The ideal height of the fence is at least 150 cm. During cold weather, pigs sleep closely huddled together. But when it gets hot, animals will want more space. Therefore, if you decide to raise pigs on a pasture-type farm, plan at least 5 square meters per pig. m.

Outdoor animals have a doubly need for protection from unpredictable weather. Provide a shelter where the pig can hide from rain and snow.

It is good if the soil in the paddock is loose or even wet. The procedure of wallowing in mud will help keep you cool in warm weather and cope with parasites. If you don't want your animals to get dirty, provide them with shady areas, which will also prevent overheating.

Place for a pigsty

As a rule, farmers place a pigsty on a site where it is convenient for them, without really thinking about whether the chosen location is correct. But a bad location can ruin the entire pig-breeding business.

The fact is that pigs do not tolerate increased dampness very well, especially if the room is full of drafts. As usual, such conditions have the most negative impact on small piglets and weanlings, who instantly become ill and remain ill for a long time, gaining weight extremely slowly. In particularly bad conditions, the mortality of young animals increases significantly.

To avoid such troubles, you should carefully look at the land plot that is at your disposal. To build a pigsty, it is preferable to choose a dry, elevated place. Areas subject to waterlogging processes or flooded by groundwater or floods are strictly unsuitable. You should also avoid places exposed to strong winds. Cold air masses will not only cool the room, but also create drafts.

Only after taking these factors into account should we move on to issues of convenience in terms of farm maintenance - the availability of access roads, laying utilities, etc.

Construction step by step

Only after the farmer has decided on the appropriate material, the optimal area and the best location for the future pigsty can construction begin. It consists of several stages, each of which must be carried out professionally - otherwise you will probably face serious difficulties in the future.

Foundation

Any construction begins with the construction of the foundation. If you choose LSTK, then there will be no problems here - due to the low weight of the structure, it is quite possible to get by with the cheapest and most quickly erected of them. Of course, we are talking about a pile-screw type. Having arrived at the site, specialists install the required number of piles by simply screwing them into the ground. This option is suitable for all types of soil and, importantly, does not require serious excavation work, and there is no need to wait for the cement to gain strength. Therefore, the entire work takes only a few days, which is highly appreciated by experienced customers.

When all the piles are installed, they are connected using a grillage. It will also serve as the basis for installing walls.

Walls

The basis for the walls is a special profile installed vertically. It is mounted on a grillage, and the length on the outer walls is much shorter than in the middle of the building. This is done specifically so that the roof installed on the profile has the desired slope - this allows rainwater to quickly drain away and also easily get rid of snow.

After installing the profile, it is sheathed with thin sheets of steel. They cannot boast of good thermal insulation, so subsequently (after installing the roof, windows and doors) they will be covered with sheets of thermal insulation material.

Sheets of steel are not always fitted closely to each other. Often small gaps are left at the top of the walls. Thanks to them, natural ventilation is carried out - it is especially effective in regions with strong winds.

Roof

After completing the construction of the walls, the installers begin to work on the roof. First, a sheathing is made from a specially selected profile - for this, the corresponding calculations are made. Roofing material is laid on top of the sheathing. Most often, a regular profiled sheet is used. This is a really good choice, since the material has a number of important advantages:

- light weight,

- high strength,

- excellent frost resistance,

- ease of installation.

However, the entire roof is not always covered with only corrugated sheets. In some cases, it is alternated with polycarbonate sheets. It allows sunlight to pass through, not only allowing you to save on lighting during the day, but also improving the well-being of animals - ultraviolet radiation destroys harmful bacteria, reducing the risk of disease.

Floors

The best material for flooring in a pigsty is wood. Yes, over time it rots and needs to be replaced. But it is the boards that provide the greatest comfort to animals, thanks to which they get sick less often and feel better.

It is necessary to leave small gaps between the boards, through which liquid waste enters special manure baths located under the floor. From here they are removed to the manure receptacle through special pipes that have a precisely calculated slope.

Windows and doors

The final stage of construction is the installation of windows and doors. They must be fitted very tightly to avoid drafts. They are especially dangerous in winter and for young piglets. Juveniles tolerate temperature changes extremely poorly - this can lead to illness and even death of animals.

The most commonly used windows are plastic windows, which provide the greatest airtightness and can cope with responsibilities for a long time even in conditions of high humidity.

Engineering systems

Heating

Also, when building a pigsty, one must not forget about heating. In the southern regions this is not very relevant - the temperature here rarely drops below zero for a long time. Therefore, with good insulation, you can even do without heating - animals generate quite a lot of heat to feel comfortable. In particularly harsh winters, you can use an electric heater or two to maintain the temperature at a sufficient level.

The northern regions are a completely different matter. When the outside temperature drops to -30 degrees or even lower, additional heating of the pigsty is necessary. And it is advisable to think about it in advance, at the construction stage.

The most economical type of heating is gas. Yes, it is more difficult to install than an electric one, but it allows you to efficiently heat a pigsty with minimal costs.

Ventilation

Ventilation is also one of the most important parameters. Moreover, it is vital.

A pigsty for 50 pigs produces several hundredweight of manure and urine per day. The latter, when decaying, releases ammonia. At low concentrations it is harmless and only causes mild discomfort due to its characteristic odor. But if the concentration increases sharply, inhaling it can lead to loss of consciousness and even death. And this applies to both animals and people.

In some cases, the problem is solved by simple ventilation - regular opening of windows and doors combined with ventilation slots. But it is advisable to consult with experts to find out exactly whether additional hood is needed in a particular pigsty.

Lighting

A very important factor influencing the well-being of animals and the convenience of working with them is lighting. In the summer, the problem is partly solved thanks to sunlight. But in winter, when the days are short, you will have to switch almost completely to artificial lighting.

Moreover, you need to draw up the right project in advance. It allows you to illuminate the entire area of the pigsty with a minimum number of lamps, without leaving dark corners in which work will be difficult.

Foundation and floors in a pigsty

Construction itself always begins with the arrangement of the foundation. The strength and durability of the entire building largely depends on it. For a pigsty, a foundation made of stone, concrete, or reinforced concrete blocks is suitable. The depth of its placement strongly depends on local specific factors (soil density and moisture, groundwater depth, etc.), so it makes no sense to indicate specific values here.

But a protruding base with a height of 20 to 60 cm should be installed above the ground surface. It is advisable to make a blind area along the perimeter of the pigsty. If there is no money for asphalt or concrete, then tightly compacted clay will do for these purposes. To prevent the walls from drawing moisture from the foundation, roofing felt should be placed on top of it.

Floors in a pigsty are a fairly important element. Both the health of the animals and the ease of maintenance of the complex depend on them. They can be made from concrete, boards and other materials. This is not as important as the floor design. If you only have 2-3 pigs, then a regular solid floor will do just fine. But for a large livestock complex with several tens and even more so several hundred animals, it is preferable to use slatted floors. We'll talk about them a little later.

Manure storage

In conventional pigsties, the manure storage facility is a large pit with a capacity of several tens or hundreds of cubic meters. Here, manure and urine are washed out of the building by gravity, along specially laid inclined grooves.

But if we are talking about a closed-cycle pig farm, then it is worth considering installing a biogas plant, in which waste will be converted into gas used to heat the building. Yes, the purchase will not be cheap. However, over time, all costs are offset by savings on gas.

Roof, ceilings and walls of the pigsty

Regardless of what material you prefer when building walls, it is important that it retains heat well and does not absorb moisture. In this case, the inside of the pigsty walls are usually covered with boards, and then plastered and covered with lime for disinfection purposes. In the northern regions, it is advisable to insulate the walls from the outside as well.

Everywhere, with the possible exception of the Southern Federal District, it is highly desirable to equip a pigsty with full ceilings, as they help retain heat in the winter.

As for the roof, there are no special requirements for a pigsty in this matter. The classic rafter-pitched scheme made of logs and slate will do just fine.

Where to begin

Business - the idea of creating a small pig farm comes to rural residents who want to get a stable income from breeding this type of domestic animal in their backyard. High quality pork, due to its excellent taste, is always in high demand and is well sold.

To organize a profitable business, it is necessary to draw up a business plan for a pig farm for 10-20 heads, which will take into account all the intricacies of home pig farming: A novice entrepreneur needs to familiarize himself with the maximum amount of information material on this type of business, analyze the information received and adequately assess his financial and physical possibilities.

Manure removal in a pigsty

Timely removal of animal waste, that is, manure, is one of the main tasks that falls on the shoulders of pig farm workers. Contrary to popular belief, pigs are not dirty animals who love to swim in puddles. It’s just that most owners don’t know how to create the right conditions for them.

In reality, pigs don't like dirt any more than any other pet. Moreover, unsanitary conditions and dirt in the pigsty are one of the main reasons for the death and illness of these animals. Therefore, maximum attention should be paid to the organization of manure collection.

As mentioned above, the optimal solution on large farms is slatted floors for pigsties. This system simplifies the cleaning process as much as possible, maintaining the cleanliness of the pens at an acceptable level.

It should be noted right away that slatted floors require the presence of special concrete baths in which manure falls. Although outwardly these bathtubs have nothing in common with the one installed in your home, they have the same operating principle. As the bath is filled, the “plug” is removed and the contents are sent by gravity to a special tank away from the pigsty. If the terrain does not allow organizing a gravity system, manure can be pumped out of the baths by force using a pump.

Of course, the organization of slatted floors requires a much more complex foundation design than when using solid floors.

Pig farm project for 100 heads

The plan for a pig farm for 100 sows is drawn up according to the area standards for 1 animal. The approved regulatory indicators are contained in the state document NTP AIC 1.10.02.001-00 Standards for technological design of pig farms for peasant farms. Based on the number of heads, the area of pens for comfortable placement of animals is calculated.

The project documentation develops a full range of construction and installation work for the construction of the farm, organizational measures for creating a water supply and sewerage network, and a plan for the electrification of the farm. High livestock productivity largely depends on creating comfortable conditions for keeping pigs. Therefore, the project shows on the floor plan the mandatory attributes of the internal arrangement of a pigsty: pens, feeders, drinking bowls, and a manure removal system is also being developed.

Lighting and ventilation in a pigsty

To ensure that pigs do not get sick and grow quickly in the pigsty, it is necessary to equip them with normal lighting and a high-quality ventilation system. In summer, it is quite possible to get by with natural light that will penetrate through the windows. But in winter, daylight hours are too short, so artificial lighting helps stimulate the development of animals.

It is believed that sows with suckling piglets need to be provided with eighteen hours of daylight, and fattening young animals at least 12 hours.

Ventilation in a pigsty is by no means a luxury, but an objective necessity. The farmer must ensure the timely removal of gases and the flow of fresh air into the room where animals are kept. Whether the ventilation system will be with natural or artificial impulse is not a fundamental question. The main thing is that there is high-quality air exchange without drafts.

Heating

In order for pigs to be comfortable and gain weight well, it is important to create a suitable microclimate in their home. Maintaining a certain temperature and humidity in the winter is especially important for small piglets that have been weaned from the sow.

The modern market offers farmers various options for heating systems for pigsties. However, the most popular today is equipment that provides animals with infrared heating, the main advantages of which are high operating efficiency and relatively low energy consumption.

The photo shows one of the options for placing an infrared heater, which helps organize convenient and economical heating of the pigsty

Heating of the pigsty and running water

Typically, pig breeding complexes do not have special heating systems, since the heat generated by the animals themselves is sufficient to maintain a comfortable temperature in the room. But the piggery, where suckling sows with small piglets are kept, should either be more thoroughly insulated or equipped with a small autonomous heating system. It also makes sense to equip a pigsty with full heating in regions where winters are very harsh.

Finally, it is worth saying a few words about the water supply of the pig farm. Animals require quite a lot of water, so for a large farm it makes sense to install a full-fledged water supply system with a pipe system in the pigsty itself. This way you will save yourself from having to manually carry cubic meters of water in order to water the pigs.

Closed cycle pig farms

For large farms, the optimal choice would be a closed-cycle farm. Its main advantage is maximum profit. The disadvantage is the need for a large number of workers and the complexity of operation. But such a pig farm receives only feed and water, and from it ready-made meat and related products.

The design of such an enterprise should be approached as seriously as possible. In some cases, it may be necessary to construct additional buildings, not to mention the purchase of special equipment such as:

- A slaughterhouse where live pigs are turned into delicious cutlets, chops, and hams.

- Biogas plants that allow you to convert manure, urine and old litter into high-quality fertilizer and gas that allows you to heat the room.

- Warehouses for storing sufficient quantities of feed, tools and equipment.

Of course, if a small number of pigs is planned, no more than a few hundred, then there is no point in such complex complexes. But a 24,000-head closed-loop pig farm is very efficient. It is not easy to achieve uninterrupted operation of such a giant enterprise. But when it is possible to organize the maintenance of a pig farm, costs will be optimized, and the quantity of high-quality product will increase sharply, which has a positive effect on profitability.

Material selection

Having decided on the project, you also need to decide on the choice of suitable material. The choice is quite large - concrete and brick, wood and light steel thin-walled structures. By the way, it is the latter that have become increasingly popular in recent years. Why? We will try to understand the main pros and cons of all available materials in order to answer this question.

Tree

A wonderful material that humanity has used for thousands of years. Its main advantages include:

- environmental cleanliness,

- low thermal conductivity,

- light weight,

- cheapness.

It would seem - why not build a pigsty from logs? Alas, there are also plenty of shortcomings here. Let's start with the most obvious - fire hazard. Yes, wood burns very well - everyone knows this. It also cannot last long in conditions of high humidity - first mold appears, and then rot.

Concrete

A very durable and strong material that is not afraid of fire or high humidity. And if you use ready-made reinforced concrete products rather than simple concrete, then building a pigsty will also take a matter of days. But reinforced concrete products are not cheap. Concrete also has a very high thermal conductivity - it is difficult to maintain the temperature in a pigsty at a high enough level. An additional disadvantage is the heavy weight. A strong foundation will be needed to support a spacious building.

Brick

The advantages of this material are quite numerous. It is not afraid of fire, unlike wood, and at the same time has lower thermal conductivity than concrete, making it easier to maintain the optimal temperature in a brick pigsty. In addition, it is beautiful, and if the manufacturing technology is not violated, it is also not afraid of high humidity.

But there are drawbacks here too. Firstly, it is quite heavy - you can’t do without a massive foundation (strip or monolithic) here either. Secondly, the cost of the material is very high, and the masons’ work itself is not cheap. Even a team of specialists will spend a lot of time constructing a spacious building.

LSTK

It is a metal frame of the building, sheathed for insulation with heat-insulating material. It is characterized by its low weight, which allows construction to be done with the cheapest foundation – a pile foundation. Another advantage is the high speed of assembly - a team of experienced installers will be able to complete the job in a matter of weeks. Immediately after, you can begin equipping and moving in the animals - unlike wood, the steel profile does not shrink.

The downside is the relatively short life of the insulation - about 20-25 years. Yes, after this time it will have to be replaced. But still, this work will not have to be done very soon. In addition, replacing the insulation will take several days. Therefore, it is not surprising that more and more farmers prefer lightweight steel thin-walled structures instead of brick or concrete.