In practice, there are mainly two methods used - manual and machine milking. It is advisable to use machine milking where there is a group of animals. The manual method is labor-intensive, takes a lot of time and effort, machines can handle it much faster and with better quality.

To get a good volume of milk and not injure the animal, it is necessary to follow the correct milking technique. Before milking, the cow's legs and belly should be thoroughly wiped with clean straw or a rag, and the tail should be tied to the leg.

If you have never milked a cow yourself, or want to improve your skills, we recommend that you read the material in this article. From it you will learn how to properly prepare a cow and milk it using manual and machine methods.

Animals begin to be accustomed to milking even before the first birth. In the second half of pregnancy, the heifer is gradually prepared for milking; she is placed in a stall where other cows are milked. The heifer hears the sounds of milking utensils, the voices of milkmaids, the noise of milking, and gradually gets used to this environment. In addition, she needs to wash, wipe dry and lightly massage her udder.

Preparing for milking

Without proper preparation, milking may not work; the cow will resist and will not want to give milk. The animal gets used to certain conditions and a consistent “ritual”. Preparation steps include:

- compliance with sanitary and hygienic conditions;

- establishing psychological contact;

- udder massage.

First of all, it is necessary to clean the barn of manure and dirt, especially the stall where milking will take place. This is necessary so as not to spoil the smell of the milk and to prevent dirt, straw, and manure from getting into it. Lay down clean bedding and it is advisable to ventilate the room. The milkmaid should be in a clean robe, her hands should be washed thoroughly with soap, and her head should be tied with a scarf.

Prevention of mastitis

Mastitis is an udder disease that can cause significant damage to farming activities. Milk from a sick cow cannot be sold or drunk, and in advanced cases, mastitis can take the life of a cow. That is why a lot of attention is paid to the prevention of this disease on farms.

Preventive measures include:

- Udder hygiene. Before and after each milking, it is necessary to wash the mammary gland.

- Massage. Heifers are prepared for lactation during pregnancy; udder massage is stopped about a month before calving.

- Inspect the milk tank daily for seals, bruises and other damage.

- Testing of expressed milk with special testers. They make it possible to identify even mastitis that occurs in a latent form.

- Lubricating the nipples with Vaseline to prevent cracks from appearing where infection can penetrate.

- Keeping litter clean.

- Organization of the correct milking regime. If you skip pumping, this will lead to stagnation and the development of inflammation.

Milking with fist

The fist milking method is the most common. The hands clasp the nipple so that the thumb is above the index finger and the little finger is on the tip of the nipple. Alternately squeezing the nipple causes the milk to move, and it flows into the bucket in a stream.

Then the fingers are relaxed to allow a new portion of milk to flow. It is advisable to collect the first streams in a separate container in order to promptly notice discharge in the form of blood and mucus and remove accumulated dirt.

Milking technology provides for a fast pace. At 80-90 compressions per minute, milk will be released almost continuously.

It is better to milk the front teats first and then move on to the rear ones. Under no circumstances should they be pulled or bent.

Preparatory stage

Before milking, the farmer puts on clean clothes and washes his hands thoroughly. Those who have scrapes or cuts on their skin should wear gloves. This measure will help prevent dangerous bacteria from entering the cow's udder. The cow's tail is usually tied to the hind limb before milking begins. The farmer sits on a low chair on the right side of the animal, and places a clean bucket under the udder, covering it with gauze folded in half.

The cow's mammary gland should also be prepared for pumping - it is washed with warm water (about 42 degrees), wiped with a clean towel. Then they do a short massage, stroking the udder first from top to bottom, towards the nipples, and then from bottom to top, to the base. During the massage, it is recommended to lift the mammary gland upward, as a calf does when it is applied to the nipple.

Massage helps increase blood circulation and stimulates milk flow and production. This is how a cow is prepared for milking on a small farm. Preparation for milking should not last more than 1 minute. The hormone oxytocin, which stimulates milk production, is produced during this period of time.

Attention! It is important to organize milking of the cow at the same time. This will increase milk productivity and avoid mastitis.

Two finger milking

This technique is only suitable for young cows with short nipples. The method is less convenient than milking with a full fist, but sometimes you have to use it.

Pinch milking technique: Holding the nipple with your index and thumb fingers, perform forward movements from top to bottom.

Manipulations should be gentle and smooth - the animal should not experience pain. The pinching technique can provoke stretching and traumatization of the teats - because of this, the cow can be irritable and even aggressive.

Proper udder massage

Massaging the udder before each milking serves not only to stimulate the production of oxytocin, but also allows you to detect pathological processes that have begun in the mammary gland. The milkmaid strokes the udder with her palms, changing the direction of movement from top to bottom, and then from bottom to top. With her fingers she probes the nipples and the base of the mammary gland, lifting it. Experience allows her to detect nodules, compactions in the udder, and determine whether it is hot. The first portion of released milk is expressed into a separate container, which makes it possible to detect impurities of pus, curdled clots or blood in it.

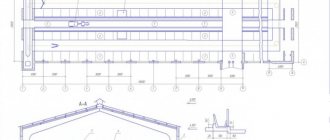

Milking chair

The milkmaid's working area should be convenient and comfortable, because squatting can quickly get tired and harm the heifer. Therefore, to facilitate the procedure, you should purchase a special low stool or make a chair for milking cows with your own hands according to the drawing.

This device is stable. During the process, it allows you to choose a comfortable position, because the more milk the cow has, the longer it will have to be milked.

Some useful things

Each milking is a little stressful for the cow. Therefore, you need to try to minimize the animal’s discomfort. To do this, before you get down to business, you need to talk to the animal and pet it. You can treat the cow with a treat - a piece of bread with salt.

It is also important not to frighten the cow, so all actions should be extremely clear and not abrupt. It happens that a cow is bothered by insects and wags her tail excessively. Then he is tied with a rope to his leg. It is very important that all actions are quick, because delay can cause a decrease in the amount of milk, it will “burn out.”

The question of how to milk a cow with your hands and a milking machine is not as difficult as it might seem at first glance. Anyone can learn this business, the main thing is desire. But if possible, it is better to purchase a milking machine, since manual milking is not an easy task, from which your hands can get very tired.

How often is a cow milked?

How many times a day to milk a cow is decided by its owner. The age and health of the animal are taken into account. The minimum frequency of milking is 2 times a day.

What you need to know when accustoming a cow to milking: First-calf heifers are milked 4 times a day for the first two weeks. Then the number of milkings is reduced to 3 a day.

The intervals between milkings must not be violated. If the mode is two times a day, the interval is no more than 12 hours; if it is three times a day, the interval is no more than 9 hours.

High-yielding cows need to be milked three times a day, this will allow: to maintain milk volumes at a high level; avoid stagnation of milk.

Types of milking machines

The industry produces a fairly large range of milking machines for different market segments. There are domestic and foreign equipment manufacturers on the market. They are characterized by productivity, degree of automation, and adjustments. Manufacturers produce inexpensive devices for small individual farms with an affordable price, with a productivity of 1-7 milked cows per hour, and powerful units capable of simultaneously milking two or more cows on large dairy farms with a productivity of up to 30 cows per hour or more. Milking machines are powered by an electric current network, which ensures the operation of vacuum blowers and automation.

The principle is the same in all milking machines, but there are two-stroke and three-stroke units. The use of three-stroke milking machines provides better milk yield results, since in the cycles of creating a vacuum differential pressure, which ensure the extraction of milk from the udder, a pause mode is provided, which is ultimately better tolerated by animals and makes the milking process more comfortable for them.

| City | Russian (rub) | Italy(RUB) |

| Chelyabinsk | from 21300 | from 37000 |

| Moscow | from 18500. | from 35500 |

| Kazan | from 22000 | from 36500 |

| Ufa | from 19900 | from 36000 |

If you follow the correct algorithm for machine milking, you can achieve high efficiency of the dairy farm and high milk yields. Follow all recommendations of milking machine manufacturers and you will not have any problems. Watch our videos in which we described in detail how to milk correctly. Judging by the reviews, machine milking of cows is used by the vast majority of farms.

The transition from manual to automated milking is justified by great benefits, especially for a large farm. When thinking about switching to mechanical milking, keep in mind that returning to manual milking is strongly not recommended. In cows, productivity often decreases and milk supply is disrupted.

Advantages

- Automatic milking has many advantages, namely:

- milk yield is many times faster than going around the herd on your own, and a large number of milkmaids is not required;

- healthy and free hands - a common disease among those who milk cows by hand is arthritis;

- The container of the device is tightly closed, no wool, debris, or dust gets into the milk;

- the milk yield has a fat content higher than with the manual method of milk collection;

- easy operation;

- low electricity consumption;

- does not require the purchase of additional devices.

Flaws

- There are several disadvantages to using a milking machine, since it:

- requires regular maintenance - if the device is oil-based, you need to carefully monitor the oil level;

- dry-type devices are noisy and require preliminary accustoming of cows to their sound;

- sensitive to low temperatures;

- does not tolerate moisture entering the pump;

- Not suitable for all cows due to the individual characteristics of the animal.

The cost of the device is not always reasonable if there is only one cow on the farm.

Machine milking works on the same principle, but the machines themselves are either 2-stroke or 3-stroke. The latter give better milk yield, since they have a vacuum pressure drop and have a pause mode - for animals such a unit is more comfortable, they are less likely to experience stress. The degree of automation of the devices varies; you can connect one cow to a portable one, or up to 20 at once. For large farms, there are milking systems designed for a number of two dozen to a hundred cows.

Today there are models on the market that are as close as possible to the natural process of milk collection. The devices are:

- Three-stroke - squeeze the nipple, express, rest, repeat the cycle.

- Asynchronous - milking first the posterior glands, then the anterior ones.

- Tact is a number equal to the sucking movements of the calf.

An equally important criterion when choosing is the type of motor, of which there are only two:

- Oil - quiet in operation, reasonable price, good for milking a large number of cows.

- Dry is more expensive than oil, is resistant to temperature changes, is lightweight, does not require maintenance and does not pollute the environment with emissions.

The classes of vacuum pumps are also different:

- Membrane - for several units of livestock, more often used in budget devices.

- Piston - not very convenient due to its large size, noise, and at the same time not the most durable.

- Rotary – almost silent.

The milk extraction method for the units is vacuum. In milking machines, an electrically driven pump creates this vacuum depending on the settings on the pressure gauge and regulator, maintaining the required pressure during the process. The pneumatic pulsator delivers pulses; you can adjust the feed speed yourself.

Tips and tricks

Experienced livestock breeders and veterinarians give preference to milking machines when it comes to milking cows.

This method of milking is more carefree for the animal itself and guarantees full milking. In addition, this method helps to collect the milk clean, without any foreign substances.

To exclude the possibility of milk being contaminated with infections, product samples should be sent to the laboratory for the necessary tests. The answer to the question why it is so important to follow this rule is quite simple.

Thus, you can be confident in the composition of your own dairy products and their quality.

Maintaining a herd of cows in order to obtain high milk yields and produce dairy products is a rather labor-intensive and responsible craft.

Success in this industry depends on the right approach and the availability of special knowledge. Milking cows is one of the most important processes that you need to learn first.

Device structure

The classic milking machine has a simple device, which includes the following parts:

- body frame on wheels, making the device mobile (there are large units without wheels, but they are rare);

- a pump from which vacuum hoses come for supplying milk and air (the pressure in them can be measured using a vacuum gauge);

- a pulsator or manifold where the vacuum line ends (in some models there is no pulsator, and its role is played by a piston pump and valves that open and close in the direction of movement of the piston);

- 4 milking cups (according to the number of teats of the cow), the outer wall of which is metal (made of food steel or aluminum), and the inner wall is covered with rubber cuffs, one of which is connected to the nipple (internal) chamber for sucking milk, and the other to the chamber between walls to create vacuum pulsation;

- receiver for stabilizing vacuum in the line (not present in all models);

- milk and vacuum tubes coming out of the glasses and entering the manifold, on which there is a valve for supplying vacuum to the glasses;

- a milk line extending from the collector and leading to a common tank;

- can with a volume of 20 liters or more, which can be made of stainless steel, aluminum or plastic.

Completion

At the end of milking, the udder and teats are examined for cracks and damage, wiped with a clean rag and lubricated with Vaseline.

Wipe and inspect nipples

In the case when the cow does not allow you to approach her and, when trying to milk her, begins to thrash and jerk, you can tie her hind legs with a rope. If it is dangerous to approach from behind, another trick is used - a loop is thrown over the front leg. The other end of the rope is tied so that the leg is in the air. The cow loses its support and does not raise its hind legs and cannot kick.

What are the mistakes?

At first glance, there is nothing complicated in milking, the main thing is that the cow does not get angry or scared. But there are little things that can harm milk production.

Mistakes during manual milking

Most errors are related to the milking mode and technique:

- Violation of the usual milking regime can lead to mastitis, sepsis, and death.

- Incomplete emptying of the udder. Leaving milk in the nipples reduces its quality.

- Enter the cow from the left side. You need to approach from the right.

Cattle distribution

One of the factors in increasing the amount of milk received from cattle is milk production. In fact, milk production is a system of measures aimed at improving the breeding qualities of an animal using proper feeding and favorable conditions.

Preparation for milking must begin long before the cow begins to produce milk. This allows you to subsequently achieve maximum milk yield. At the same time, only completely healthy and well-developed cows can be milked intensively. An important condition for the effectiveness of the process is complete and balanced feeding of livestock and highly qualified service personnel.

Breeding can be individual, group or combined (individual-group). It is the latter that is most often used on farms. It is carried out as follows:

- The diet is divided into classes, taking into account the calving of cows and their productivity. Animals with the highest milk yields are given additional feed (concentrates, root vegetables, cake, bran and others). At the same time, milking of calved cows begins 12-14 days after calving. Also, when forming a diet, the cyclical nature of the lactation period is taken into account.

- Control milking is carried out regularly (at least once a decade), based on the results of which the diet is adjusted.

- To distinguish cows of different classes, bright tokens of different colors are used.

Udder problems

Udder swelling

Most often, udder swelling occurs in animals that have spent the entire pregnancy without movement, and the diet was dominated by succulent and sour foods. First, swelling appears in the area around the nipples, and sometimes on the nipples themselves, then it rises higher and affects the entire udder. Swelling of the nipples is more dangerous - it can spread to the lower abdomen and reach the chest. During swelling, the skin of the cow's udder noticeably thickens, and when pressed, clear fingerprints remain.

Udder swelling occurs due to the predominance of blood inflow over outflow. Swelling of the udder can occur in the first three months of pregnancy if the cow has a problem heart, kidneys, or toxicosis. If the disease is treated, the swelling goes away on its own. During prenatal edema, it is recommended to give out milk little by little. The cow is given less water and treated with drugs containing calcium: disalunil or urodiacin. It is good to relieve swelling with a massage with bismuth zinc ointment.

If a tumor is palpable on the udder, the swelling can be relieved using a novocaine blockade. Alternating cold and warm compresses also helps.

Blood in milk

The reasons for the presence of blood clots in milk can be of a very different nature. The entire udder or part of it may become infected. The diseased area of the udder swells, compactions can be felt in it, and the milk changes its consistency and becomes more watery. If there is little blood in the milk, then the cow continues to be milked. Before each milking, massage the udder well. For minor blood stains, use the following remedy:

- Vitamin C,

- Vitamin K with calcium,

- Adrenaline injections,

- Hemostatic drugs.

If blood spots are caused by ruptured blood vessels, no treatment is required. After a few days, the vessels will recover on their own. If the reason for the appearance of blood in the milk is cracks in the skin of the nipples, then after milking it is necessary to treat the nipples with a two percent solution of soda and ichthyol ointment.

More dangerous causes of milk with blood are tuberculosis and abscess. To prescribe treatment, you must contact a veterinarian.