Despite the huge variety of modern materials in the construction markets, wood still remains the most in demand. But unfortunately, it has a main drawback - with high humidity, it begins to become moldy and may even begin to rot. But in order to avoid these negative consequences, you need to take care of this by treating the wood with special solutions.

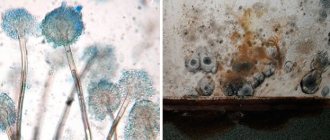

Mold on wood

Causes of wood rotting:

- more than 80% increase in indoor humidity;

- high humidity of the tree itself;

- no air circulation;

- condensation forms;

- from severe frost and insufficient protection of the wood, it freezes;

- comes into contact with the surface of the earth;

- condensation forms.

Mold damage to a wooden surface

Methods for preventing mold and mildew:

- You cannot use freshly cut wood - it must dry for about a year;

- it is necessary to waterproof the apartment and other rooms so that there is no “dew point”;

- carry out protective work against atmospheric humidity with specialized impregnations and paints and varnishes;

- To prevent condensation from forming, it is necessary to make a vapor barrier on the inner surface of the walls, and thermal insulation on the outside.

Removing mold from wood

Reasons for appearance

Mold is a fungus that reproduces by attaching and propagating spores. Individual boards or the entire bathhouse become a site of fungal attack only when favorable conditions occur. These include:

- high humidity;

- elevated temperature;

- insufficient air circulation in the room.

In order to choose the optimal control method, first determine the cause of the formations. Methods include both measuring temperature and humidity using special instruments.

Folk recipes for protecting wood from mold and mildew

There are the following methods of treatment with folk remedies:

- The method is to treat the surface with silicate glue. To do this, you need to take it and dilute it with water until a fluid solution is formed, the main thing is that it is not too liquid. The resulting solution should be used to saturate the wooden structure of the walls of a cellar, basement, etc.

- method - this will be a method using more complex components - such as 5% solutions of potassium dichromate and sulfuric acid. These components must be combined in a 1:1 ratio and impregnated with wood.

- The method is much simpler compared to previous methods, since it requires components that are quite common in everyday life - soda and vinegar. Apply baking soda to the moldy area, and sprinkle vinegar on top, possibly using a spray bottle.

- method - this method is used by treating the walls with copper sulfate (about 100 g). It can be purchased in stores dedicated to gardening; in addition, it is often found in construction markets. To begin with, it should be diluted in 10 liters of ordinary water. To increase the effect, add 1 tbsp to the mixture with Copper sulfate. l. vinegar. Now you need to mix everything thoroughly. And then treat the required surfaces with copper sulfate. This substance is considered toxic.

Copper sulfate helps prevent mold from growing on woodAfter treating surfaces with copper sulfate, for safety reasons, you should leave the room until it dries completely (2-3 days). This method is perfect for treating cellar walls.

- method - you need to make the following solution: mix 5 liters of boiling water with 50 g of Boric acid and add 1 kg of table salt. The surface should be soaked with this solution a number of times at intervals (approximately 2 hours).

The methods considered will be effective if mold and mildew occupy a small part of the surface. If the affected area is large enough, then more serious methods should be used.

Sequencing

To combat pathogenic flora that destroys wood, it is important not only the product, but also the preparation of the surface.

To achieve maximum effect, you need:

- Choose suitable conditions - the outside temperature should not be lower than 5℃. Sunny, warm and dry weather is considered optimal.

- Prepare the surface - use a metal brush to remove any lesions and allow to dry thoroughly.

- Apply the product - if the damage is deep, it makes sense to apply the treatment 3-4 times, leaving time intervals for complete drying.

- Treat with a protective coating - to protect the wood from further destruction, after disinfection it is necessary to open it with paint and varnish compounds that prevent the absorption of moisture and the development of rot.

Have you ever had to deal with mold on wood?

It happened, it didn't happen

It is recommended to destroy peeled wood shavings with obvious signs of mold. The best way is to burn it in a fire. If you throw it in the trash or bury it in the ground, the fungus will continue to exist, and its spores can reappear on wooden surfaces.

Preservation and application of antiseptic

Experts believe that the most effective methods are preservation and coating with an antiseptic.

Canning is the coating of materials with special substances. Such impregnations as:

- diffusion;

- autoclave

As a rule, preservation is carried out in a high-pressure vacuum. This is a special advantage in which this composition penetrates quite deeply.

Treat with an antiseptic - means superficial penetration, which prevents the appearance and proliferation of unwanted substances.

Antiseptic treatment against mold

Methods used when applying antiseptics:

- using a brush;

- using atomizers or sprayers;

- by immersing materials in a specialized antiseptic solution. The solution can be either hot or cold.

Protective compounds used in surface treatment:

- antiseptics;

- various types of paints;

- varnishes

By painting, wood can be protected from moisture, while creating the most aesthetically pleasing appearance for this material. As a rule, for processing material inside a building (in an apartment, for example, or in cellar buildings), you need to use water-soluble paints, and for exterior work - only those made with an organic solvent.

By varnishing wood, you can not only end up with a beautiful matte and glossy finish, but also get a special film that will protect the wooden surface from moisture and fungi, prevent the product from fading and, thanks to it, prevent destruction.

Antiseptics are used most often when the wood is already susceptible to mold.

Types of antiseptics:

- water-soluble products. These products do not adversely affect humans and various animals. They dry quite quickly. You can buy them in two types: there are powder and aqueous solutions. Such solutions are actively used when treating walls, etc. in an apartment and other rooms. But you cannot use this type of antiseptic where the wood comes into direct contact with water.

- another type is water-repellent. They are characterized by significant, compared to the first type, penetration into the wooden structure. These types have a strong odor. They are actively used for baths, saunas, as well as basements and cellars - where the humidity is high.

- antiseptics that are made on the basis of solvents. They are used to treat surfaces both externally and internally on walls, floors, etc. Treatment with this antiseptic dries for up to 12 hours.

- oil products. The main feature of these products is that they must be used on dry surfaces, otherwise the fungus will corrode the wood from the inside.

Use of oil-based wood treatmentsIn this case, a special film is formed on the surface, which protects the desired surface for a long time. Such protective equipment cannot be used in an apartment or other residential premises.

- combined means of protection. They are designed for use in various rooms under any conditions, even for the walls of the cellar and basement. Their main feature is good fire safety.

As they are absorbed, antiseptics are divided:

- for glazing - they are colorless and do not change the color of the surface being coated;

- covering compounds. They penetrate quite deeply, changing the color of the wood.

Antiseptics should also be distinguished by purpose:

- for interior work indoors;

- for outdoor.

For example, paint and varnish antiseptics can be used for exterior work, because they are not negatively affected by external factors. Products intended for work inside are, as a rule, resistant to mechanical influences, but not resistant to ultraviolet radiation and significant temperature changes.

When choosing a means of protecting wood from fungal deposits and mold, you should know the characteristics of each type, and already purchase a product that is suitable for your surface.

Antiseptic treatment of all wooden surfaces

Kinds

The type of mold determines the choice of method that will help you effectively deal with it forever.

Black

Black mold is the most active and fastest growing of all. It usually destroys the surface quickly. There are several strains that cannot be distinguished from each other without special research.

It is very dangerous for humans, as if it enters the body it causes poisoning and allergies. Fighting black mold is quite difficult - it is not susceptible to most folk and chemical preparations.

Xin

Blue is not so dangerous for the human body, but it causes destruction of structures. Affects fresh and old wood, leading to its rotting. Particularly dangerous for load-bearing structures.

Putrefactive fungus

Putrefactive fungus spreads under conditions of high humidity in the room and the presence of external sources of moisture. Antiseptics and home methods can cope with it.

See also

How to clean a pond at your dacha with your own hands, step-by-step instructions and care rules

White

White mold affects not only furniture, but also food. It is easy to deal with, since it is not resistant to aggressive drugs. It does not pose any significant danger to the body.

Features when processing wood surfaces

Thanks to the film that forms on the wood, the coating is reliably protected from moisture and pests. But the problem is that it is difficult to evenly distribute the protective agent over the entire surface due to the unevenness that exists on the wood.

Due to the variety of types of wood, they are impregnated differently.

For example, it is difficult to use antiseptics on coniferous trees; also species such as ash, beech, and birch have a high level of resistance to these agents.

A lot depends on the moisture content of the wood, so you should first dry the material and only then treat it with an antiseptic.

Prevention methods

The set of preventive measures will take less time than treating a simple fungus at home. Problems are easier to prevent, so it is important to ensure their ventilation in a bathhouse or wooden house.

Hydro- and vapor barrier

The main reason for the formation of pathogenic microorganisms is excessive humidity levels and the influence of steam. It is important to protect furniture and structures from this. Therefore, it is imperative to use special varnishes that protect the wood.

In a room where the humidity is always exceeded due to objective factors, for example, in a bathhouse, it is necessary to ensure a pleasant microclimate and regular ventilation.

Roof and foundation integrity

Before putting the house into operation, the roof and foundation must be covered with paints, varnishes and antiseptics. The appearance of fungus in these structures is not always noticeable, but as a result they grow and cause harm. Cleaning and application occur only on a clean surface; brushes, sprayers and rollers are used.

Vapor barrier membrane for protection against condensation

A vapor barrier membrane will protect against condensation and serve as an additional measure. The event is presented as a whole.

Let's sum it up

The defeat of wooden structures by any type of mold is a serious challenge that must be accepted and fought against this evil.

Today you have at your disposal a whole range of folk remedies and special antiseptic preparations produced by the chemical industry. It must be admitted that industrial antiseptics still benefit in efficiency and duration of action and fully justify their cost.

If your attic, shed, or any other area where woodwork or trim is present does not reveal any signs of mold on close inspection, consider applying a protective antifungal treatment in some suitable manner and ensure healthy conditions - good ventilation, normal humidity, absence of significant temperature changes in rooms, waterproofing of lower wooden structures. This will create big problems for mold, and in combination with protective treatment will reduce the likelihood of infection to a minimum and maintain a healthy environment in the premises.

TOP 5

- Let's start with the fact that wood is a porous material and, once it gets deep, nothing prevents the spores from developing. They feel warm and comfortable there, the main thing is that there is water.

- In addition, the wood itself is hygroscopic; if the surface is not properly or insufficiently treated, the wood can quickly become damp and, in fact, turn into a breeding ground for mold.

- And finally, wood is a living, biologically active material, which the fungus actually feeds on during its development. It's like putting a sweet tooth in a confectionery shop.

In the underground, the top layer of soil is removed, a cushion of clay, lime and crushed stone is poured in, and compacted thoroughly. The layer will protect the space under the floor from the formation of cracks and provide good ventilation.

Sulfur checker

If you don’t know how to get rid of mold in the basement of a wooden house, use a sulfur bomb. This is a fine aerosol that, when combined with air, forms a deadly mixture for fungus and its spores. At the same time, the smallest particles easily penetrate the narrowest crevices of wooden surfaces, being an effective way in the fight against mold.

Ways to fight

- Degtyarnoe. A strong antiseptic for self-removal of dirt, impregnation of log walls and floors. The composition penetrates deep into the boards and remains there thanks to the linseed oil in the composition.

- Tung. Suitable for interior work, as well as impregnation of valuable wood species. The composition quickly penetrates the wood layer, highlighting its texture.

- Linen. It has high waterproofing properties, penetrates into small cracks, clogs them, forming a durable water-repellent layer. The oil dries for about 3 weeks; to speed up the process, turpentine, tar or wax are added to it.

- Teak. A universal product for working in wet areas, processing log structures inside and outside the house. Before use, teak oil is not diluted, mixed and coated with infected areas.

Several types of molds can grow on wood. The most common of them:

Folk remedies Recipes for masks At home Hair loss in women How to stimulate growth Causes of hair loss Hair loss in men Review of vitamins Helpful tips