Harvesting hay

An important factor in obtaining high-quality hay is harvesting grass in the early phases of the growing season. The high content of nutrients and vitamins in young herbs is explained primarily by their foliage. The leaves contain 2-2.5 times more digestible protein and 10 times more vitamins than the stems. In young legumes, leaves account for 40-50% of the mass. As plants age, the ratio of leaves to stems changes towards an increase in the latter, the content of nutrients and their digestibility sharply decrease.

The development phases of forage crops change quite quickly. Therefore, harvesting grass for hay for each type of hayfield should begin at the optimal time and be completed within 8-10 days. Delays in harvesting lead to an unreasonably large shortage of the most valuable nutrients. Thus, when harvesting a clover-cereal mixture during the budding period, 1 kg of dry matter of hay contains 150 g of digestible protein, 270 g of fiber, 35 mg of carotene, at the end of flowering - 90, 360 and 12 mg, respectively. Protein digestibility decreases from 65 to 45%, and fiber digestibility from 64 to 52%. The amount of digestible protein in 1 kg of hay decreases from 98 to 40 g, feed units - from 0.46 to 0.33. Early harvesting of grass allows you to get a full second and even third cutting.

The optimal time for harvesting legumes and cereal grasses to obtain high-quality hay is the budding phase; for cereals, it is heading. Their harvesting should be completed at the beginning of flowering.

What to feed the animals?

You need to know exactly what to feed the animals, because they all prefer different hay. This is due not only to the type of livestock, but also to their age. For example, a grass that is great for adults has a negative effect on little ones. Choosing the right feed is very important to keep your livestock healthy.

So which grass is best for farm animals? Everyone has different needs:

- Grain and legume (alfalfa) hay is more suitable for horses. Dried grass for these animals must be clean, free from dust and mold. Otherwise, horses will have health problems, pregnant mares may lose their offspring, and colic will be provoked in stallions. The ideal option for feeding a horse is cereal hay, as it is rich in calcium and phosphorus. Grain hay is suitable for foals and pregnant and lactating mares as it is rich in protein.

- Cows are not picky about hay. They can even eat dusty or slightly moldy grass. Cows that are raised for meat can be fed any type of hay, but lactating cows need cereal, which is high in protein. The best way to feed dairy cows is to give them good alfalfa hay. The more nutrients the mare receives, the more milk she will produce and the tastier it will be.

- Goats should be fed grain and legume hay, but not fed these types separately. Pure legumes (from vetch, clover, alfalfa, soybeans or lespedeza) are ideal for feeding kids and adult goats that are nursing foals or are pregnant. There should be no dust or mold on goat hay.

- Good leafy hay that is not coarse is suitable for sheep and rams. Adult animals need to be given high-quality cereal hay, but lambs need bean hay with thin stems, that is, cut during the growing season.

- Rabbits eat legume and cereal hay. It is the most nutritious, moderately coarse. Also suitable for these animals is dried grass from meadow and steppe herbs, which was mowed during the flowering of the plants and dried in the shade. Meadow and steppe proper hay will be especially useful for pregnant and lactating females and rabbits.

- Poultry is also fed hay in the winter. Ducks, geese, and chickens eat cereals, legumes, and wild grass. It is better to make preparations before flowering, since in this case more valuable substances for birds will be retained in the herbs. They are suitable for meadow timothy, awnless brome grass, and hedgehog grass. You can even make hay from the leaves of poplar, aspen, linden, birch, yellow acacia, and alder. Such products will be rich in vitamins and minerals. Poultry hay must be chopped.

It is necessary to remember all the listed features of the types of hay and give it only to those animals for which it is really suitable. If the wrong dried grass is given to livestock, it will negatively affect the health of the livestock.

Mowing and wilting herbs

In dry, clear weather, the timing of mowing any type of hayland is not a determining factor. If there is precipitation or morning dew, the grass can be mowed only after good ventilation. Otherwise, drying times are extended and nutrient losses increase sharply.

It is better to mow grass with a high yield of green mass using mowers such as KS-2.1, KDP-4, rotary mowers KRN-2.1, KPRN-3, etc.

When harvesting seeded legumes with flattening, it is necessary to use mowers KSP-5, E-301 and E-302. Flattening is used when harvesting coarse-stemmed leguminous grasses (clover, alfalfa) when their content in the grass stand is more than 30%. In unstable, rainy weather, flattening should not be carried out. This increases nutrient loss. Flattening of cereal grasses in clean crops is ineffective.

The technology for wilting herbs should ensure a rapid reduction in plant moisture to a level of 45-50%, at which biochemical processes are sharply inhibited and nutrient losses are reduced. This can be accelerated by flattening the stems and turning the mass. To teddy the grass in swaths, raking it into windrows, wrapping and spreading the windrows, you should use GBK-6.0, E-247 rakes or special windrowers.

Tedding of mown grass is especially necessary in high-yield areas, where it lies in an uneven, dense layer. The first tedding should be carried out simultaneously or immediately after mowing, while the mass dries, is better blown by the wind, and drying occurs evenly and faster. Subsequent tedding is carried out as the top layers dry. Withering in swaths is completed when legumes reach a moisture content of 55-60%, and cereals - 40-45%. After this, the mass is raked and dried to the required level in windrows without tedding, depending on the hay preparation technology (loose, crushed, pressed).

Herbs mowed into a windrow especially need 2-3 times tedding and turning, since a thick layer of mass is dried for a longer time.

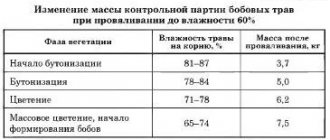

In order to carry out the next technological operation in a timely manner when harvesting hay, it is necessary to regularly determine the moisture content of the mass throughout the entire period. You can control changes in the moisture content of mowed grass using a Chizhova moisture meter. In the absence of this device, changes in grass moisture can be determined by periodically weighing it from a permanent area (1-2 m2). {reklama} The first weighing of the grass is carried out immediately after mowing. A sample of the green mass is taken, dried in an oven and the moisture content is determined. Subsequently, the moisture content of the mowed mass is determined by the difference between the first and last weighing of the mass at the recording site.

Of the existing methods of making hay, the most widespread is the preparation of field-dried loose hay. With this harvesting method, losses can reach 35%. Therefore, field drying of herbs should be regarded as a necessary measure when more progressive methods of hay harvesting cannot be used. To obtain high-quality hay using this method, all technological methods must be carried out strictly in accordance with the requirements.

Stacking

Hay harvesting ends with the hay being placed in a stack or stack for storage. A haystack is most often made round, about 6 meters high, with a diameter of about 2 meters. A haystack of this size is convenient to cover and use; the hay is protected from freezing and getting wet. To prevent the haystack from falling and being blown away by the wind, a pole is dug in the center, which is first covered with straw and then with hay. For strength, you can dig several poles diagonally from the central one. The formation of a haystack begins by laying it along the edges, and the central part is laid out last. The second and subsequent layers are shifted inward from the edge, gradually reducing the diameter. Once the haystack is formed, a wooden rake is passed over it and covered with twisted branches, a tarp, and tied with ropes.

Hay harvesting technology

The mass, dried to 30% humidity, is collected in windrows using a PK-1.6A pick-up stacker and left on the field for several days. In the stacks, the hay is dried to a moisture content of 20%, and then transported to the place of stacking by draggers, hay haulers KUN-10 or KUN-11. In dry weather, during transportation and stacking, the hay is quickly dried to a standard moisture content of 17-18%.

In the absence of pick-up stackers, the mass from the rolls can be picked up without crushing and loaded into vehicles using the E-062/1 mower-loader.

In the absence of storage facilities, it is advisable to transport hay to livestock complexes and farms and stack it in large stacks and stacks (at least 35 tons) on specially prepared sites.

A more advanced technology is the preparation of compressed hay. With this technology, labor costs are reduced, losses are reduced by 2-2.5 times, storage is used more rationally (it can hold 1.5-2.5 times more hay) than when harvesting loose hay.

When harvesting compressed hay, the technological process of wilting grass on the field is the same as when harvesting loose hay, however, the moisture content of the mass during pressing should be higher (within 22%). The drier the grass, the higher the mechanical losses. When the humidity of the mass is above 24%, there is a threat of self-heating and molding of the hay, and its quality sharply decreases.

To press hay from windrows, balers PSB-1.6, PS-1.6, K-422, K-453 are used with bales tied with twine. The compaction density at the specified humidity should not be more than 140 kg/m3. In favorable weather, the bales are left on the field for 2-3 days to dry. To do this, the bales are placed in a pyramid so that four lie edgewise on the ground and two on top. The pyramid of bales is well ventilated, and the hay dries quickly. A pyramid of six bales can be loaded onto a trailer using a haystack thrower.

Description

How to make hay? Hay is dried grass, which is the basis of nutrition for farm animals in winter. This product is fed to large and small livestock (horses, sheep, cows, goats, rabbits, pigs), as well as ducks, chickens, geese and other poultry. Only in the second case less dried grass is needed. The quality of hay depends not only on the grass itself. In order for hay to be nutritious and retain the entire complex of vitamins, it must be prepared correctly. This process has its own characteristics. Information about the nuances of hay harvesting (cutting, drying, storing) is presented in the article.

Homemade hay mower

Even on a small farm, haymaking is much easier if you have a haymower. You don’t have to buy it—the simplest model is easy to make yourself.

The base of the mower is a frame, which is made from a metal profile or angle 40 by 40 mm. The frame is welded and wheels for bearings are installed on it. The use of two discs means the presence of eight knives made of durable alloy, which are easy to sharpen even at home. To install the knives into the discs, you need to make eight holes, 6 mm deep, and attach the knives themselves with a millimeter gap. Disks with knives are welded to the frame, and then a connection is established between the drive from the chainsaw gearbox and the disks using a chain.

This homemade mower can be used together with a small tractor or walk-behind tractor.

Homemade pitchforks

For hay harvesting, stacking and tedding, pitchforks are needed. The length of the sharp tines must not exceed 65 cm, and the total length of the forks must be at least two meters. Homemade hay forks can be easily made from a wooden handle and high-strength metal rods with a diameter of at least 1 cm. The rods are cut with a grinder into four equal sections, 60 -65 cm each. A section of a strong steel pipe is used as a crossbar, to which a welding machine and weld the teeth. For convenience, the teeth can be bent - this will facilitate the stacking process. A groove is welded onto the opposite side into which a wooden handle will be inserted. The handle is securely fixed with screws.

The main advantages of haylage over silage

Before preparing haylage, it is necessary to take into account the main features of this type of feed and its advantages over silage:

- The minimum loss of nutrients does not exceed 10%. Due to this, high levels of sugars and carotene are maintained.

- Humidity levels of up to 55% ensure good palatability of the feed, which contributes to increased milk production.

- Haylage is prepared from alfalfa and legumes and cereals, which guarantees its balance in proteins and energy.

- Due to the minimal level of moisture, haylage is perfectly stored for a long time, does not get wet or freeze.

- The food is prepared without the use of preservatives, so it has a completely natural composition.

For home use, haylage in bales is most suitable - it is characterized by minimal labor costs and short harvesting times.